Technologies

Technologies: Reference & Compare

We are proud to run some of the industry's most cutting edge additive manufacturing technologies. We are often first in the industry and even first in the world to embrace new additive manufacturing innovations.

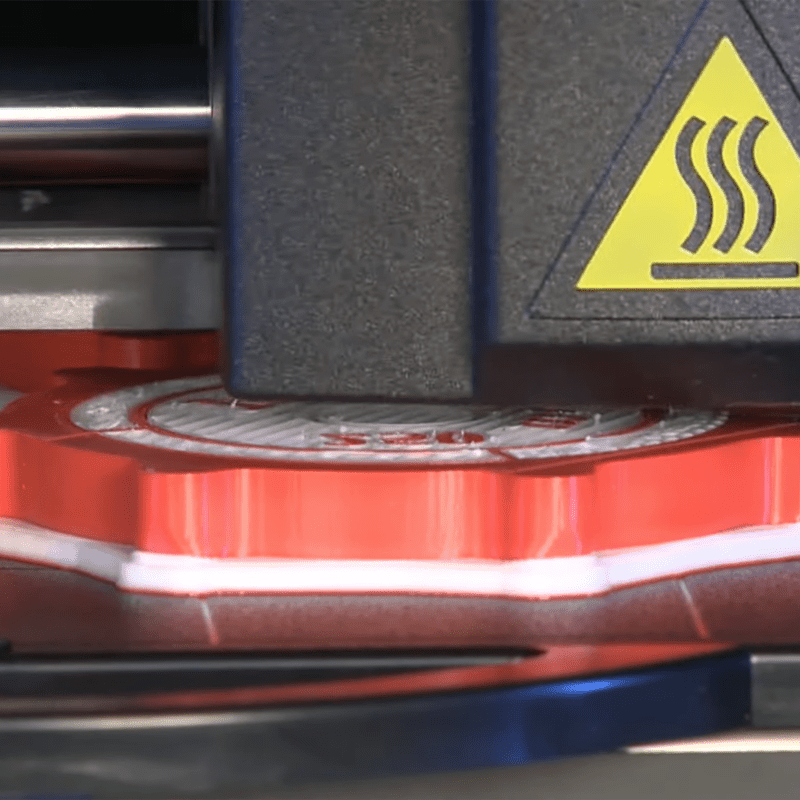

Multi Jet Fusion (MJF) – Ultra White

Unique Advantages:

- High structural performance

- End-use quality surface

- Precision dimensional accurate

- High volume production

- Complex, functional prototypes

| Gallery | View |

| Average Tolerance | +/- 0.008 per inch |

| Materials |

Nylon PA12 - Ultra White |

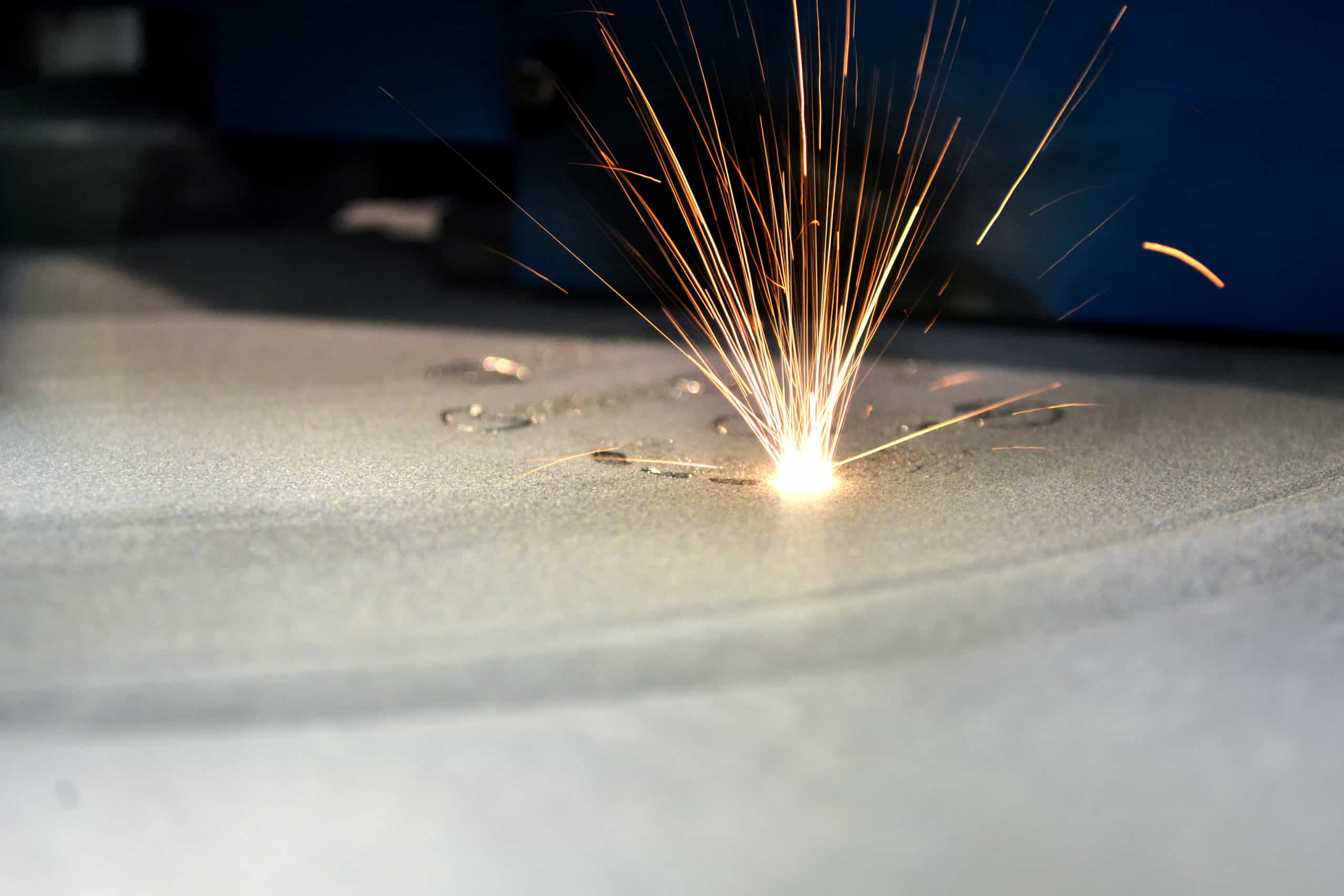

Laser Powder Bed Fusion Metal

Unique Advantages:

- Production-grade metal components

- Complex shapes

- Part size and weight reduction

- Properties comparable to wrought metals

| Gallery | View |

| Average Tolerance | |

| Materials |

Metal - 304 L Stainless Steel Metal - 4340 Steel |

Multi Jet Fusion (MJF) – Full Color

Unique Advantages:

- Full color aesthetics

- Optimal mechanical properties

- High dimensional accuracy

- Complex, functional prototypes

- Full volume production

- Mass customization capabilities

| Gallery | View |

| Average Tolerance | +/- 0.008 per inch |

| Materials |

Nylon PA12 Full Color |

No Further Technologies

| Technology | Unique Advantages | Gallery | Average Tolerance | Materials | |

|---|---|---|---|---|---|

|

View |

+/- 0.008 per inch |

|||

|

View | ||||

|

View |

+/- 0.008 per inch |

|||

|

View |

+/- 0.008 per inch |

|||

|

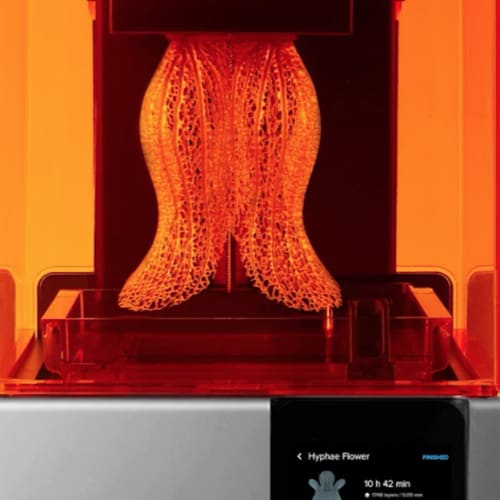

View |

+/- 0.005” for the first inch plus +/- 0.002” for every inch thereafter |

Dental Prototype Resin - DPR 10,

Elastomeric Polyurethane - EPU 40,

Elastomeric Polyurethane - EPU 41,

Epoxy Resin - EPX 82,

Flexible Polyurethane - FPU 50,

Henkel Loctite IND 405 Clear,

High Temp Rigid - Cyanate Ester - CE 221,

Multi-Purpose Polyurethane - MPU 100,

Prototype Resin - PR 25,

Rigid Polyurethane - RPU 130,

Rigid Polyurethane - RPU 70,

Silicon - SIL 30,

Urethane Methacrylate - UMA 90,

|

||

|

+/- 0.0015” for the first inch plus +/- 0.0005” for every inch thereafter |

||||

|

View |

the greater of +/- .200 mm (.008 in), or +/- .002 mm/mm (.002 in/in)(dependent on material) |

|||

|

Get a quote or set up a consult

Finding the right technology for your project or part can require in-depth knowledge and materials expertise. Try out our online quote tool or request help from one of our additive manufacturing experts.