A Team Fueled by Solutionology

For this episode of the Solutionology Podcast, we brought in some very special guests - our DI Labs team members! To kick off the discussion, co-owners Carl, Brian, and Sean Douglass share their unique definitions of solutionology, a mindset that was shaped by their entrepreneurial father and is the fabric of our culture. Next, each team member shares how solutionology drives the work they do every day. Solutionology is our fuel, additive manufacturing is our toolbox and a talented, driven team is our DI Labs differentiator!

Solutionology Podcast

Solutionology Podcast: Episode #6 | Introducing Ultra White

In this episode, we share some exciting news about the latest advancements in additive solutions at DI Labs. We've added Ultra White to our core capabilities powered by HP’s 5420W, a new generation of Multi Jet Fusion (MJF) technology that is currently being launched at Formnext in Germany!

Solutionology Podcast: Episode #5 | Advancements with White Parts

DI Labs is always seeking opportunities to be on the cutting edge and push boundaries. In this episode, we share some exciting news about the work we've been doing with white nylon parts.

Solutionology Podcast: Episode #4 | The “Art” of Onboarding Materials & Technologies

In this conversation, the three Douglass brothers, who are owners of the business, provide an update on the "Free the Fortus" OpenAM beta. That leads them into a much deeper discussion about just what it takes to onboard new materials and new technologies. Enjoy!

No Further Videos

Opportunities With Additive

Next Generation Product Innovation Powered by a New Way of Thinking About Additive Manufacturing

The next generation of product innovation is here, powered by a new way of thinking about additive manufacturing.

From Traditional Manufacturing to a Dynamic Product Platform

Additive manufacturing capabilities are accelerating rapidly, creating opportunities to approach product innovation differently. What was once a single product manufactured in mass quantities can now become a dynamic product platform. See our case study.

No Further Videos

About DI Labs

A Team Fueled by Solutionology

For this episode of the Solutionology Podcast, we brought in some very special guests - our DI Labs team members! To kick off the discussion, co-owners Carl, Brian, and Sean Douglass share their unique definitions of solutionology, a mindset that was shaped by their entrepreneurial father and is the fabric of our culture. Next, each team member shares how solutionology drives the work they do every day. Solutionology is our fuel, additive manufacturing is our toolbox and a talented, driven team is our DI Labs differentiator!

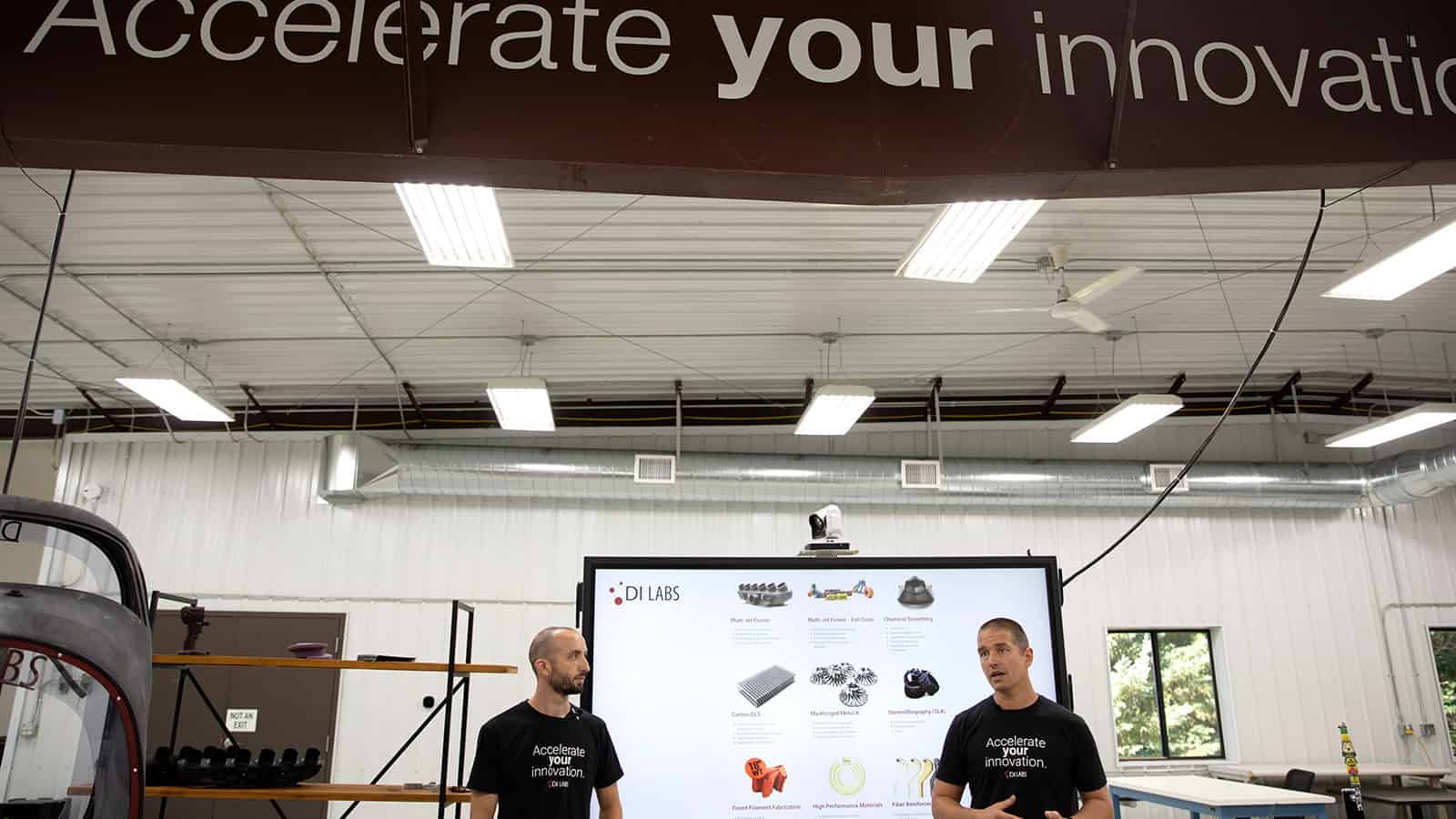

The Story Behind Our DI Labs Culture

The DI Labs culture is like none other and can be hard to describe. It's what makes us different and what drives our highly innovative, creative and relentless approach to problem solving. Listen to this podcast-style conversation with Co-Founders Carl & Brian Douglass to learn more. For more info about our engineering-first approach to serving customers, check out our Solutionology Podcast on YouYube!

Facility Tour: Experience the Future of Product Innovation

In 2020, we did something that's rarely done – gave our customers and the public a live, behind-the-scenes, transparent look at our state-of-the-art 3D printing facility in full production deploying some of the world's most cutting-edge technologies.

No Further Videos

Project Profiles

N95 Mask Alpha Prototype

For this prototype, we used our industrial-grade Multi Jet Fusion technology with certified nylon PA12 material to achieve a smooth surface then applied a vaporfuse finishing technology to seal the surface of the mask, making it washable, moisture-resistant, and sanitizable for hygienic, repeat use. See our full case study for more details.

Full Scale Prototype Bigger Than the Printer

This full scale prototype was an extremely complex additive manufacturing project. Our aerospace customer required a full-size fuselage model with a high degree of dimensional accuracy so they could perform internal testing for ergonomics, cockpit design, and operation. See our full case study for more details.

Custom Designed Face Shield for Food Processing

A national food processor needed custom-designed face shields for their front-line workers. They required an immediate solution and off-the-shelf products weren’t working. Within days from meeting with them, we were in full production of face shields tailored to their ergonomic and safety requirements. See our full case study for more details.

No Further Videos

Case Studies

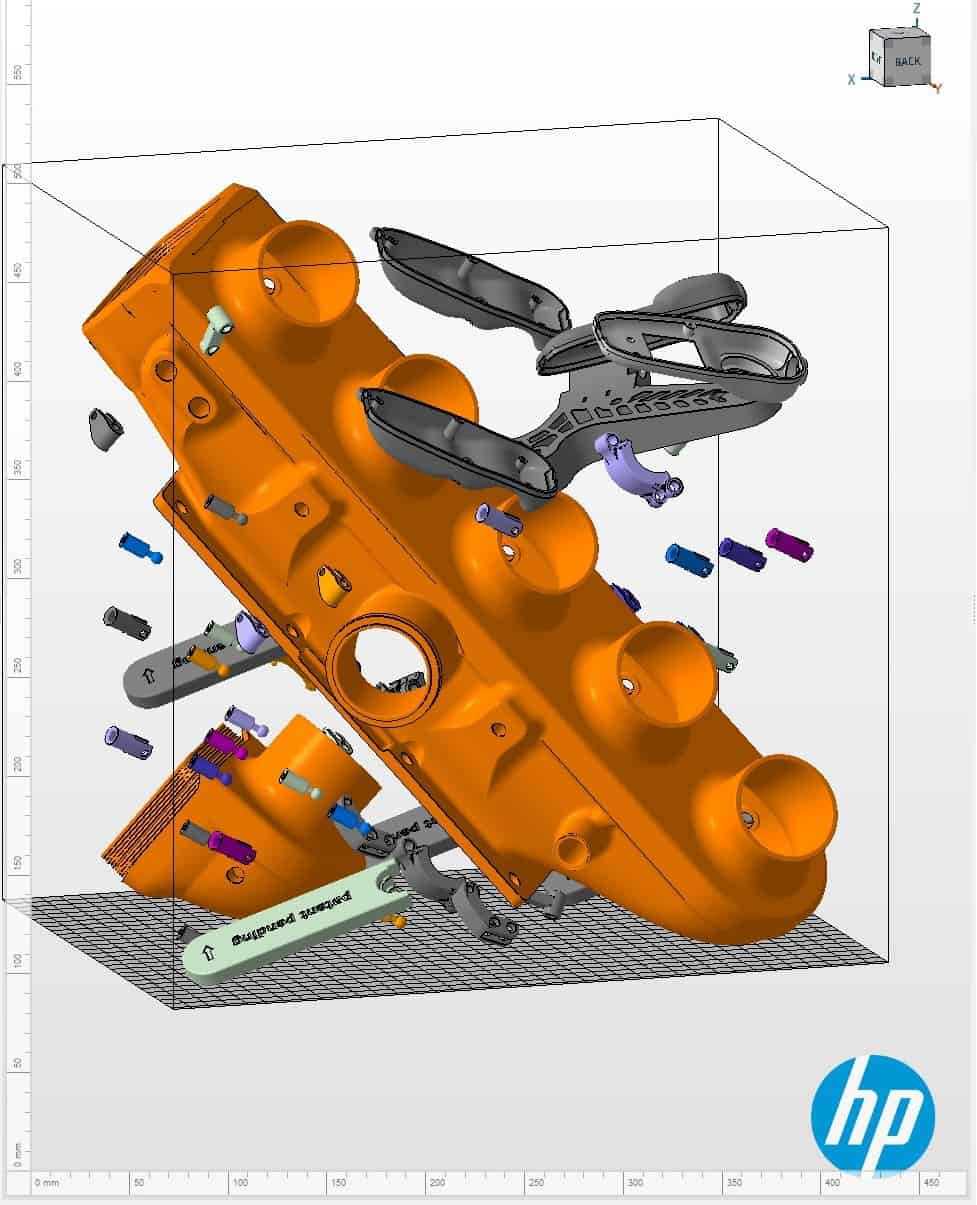

Functional Automotive Intake Manifold

DI Labs was approached by an aftermarket automotive tuning company doing work for European sports cars. They were interested in developing a fully functional prototype of an intake manifold that would accept their supercharger and create forced induction. See our full case study for more details.

Aeroponic Basket Design Increases Productivity

DI Labs custom-designed an aeroponic basket for an organic farming operation that not only met their strategy but increased lettuce production by over 30%. Over a period of three months, DI Labs delivered 10 iterations of new basket designs, each in quantities of 1,600 units. See our full case study for more details.

Perforator Sleeves Save Expenses & Time to Market

Our client manufactures plastic tubing and was scaling the launch of a new product which was being produced on existing equipment, which would not perforate the new product without modifications. We used 3D scanning to reverse engineer the equipment and design adapter sleeves. See our full case study for more details.

No Further Videos

Education

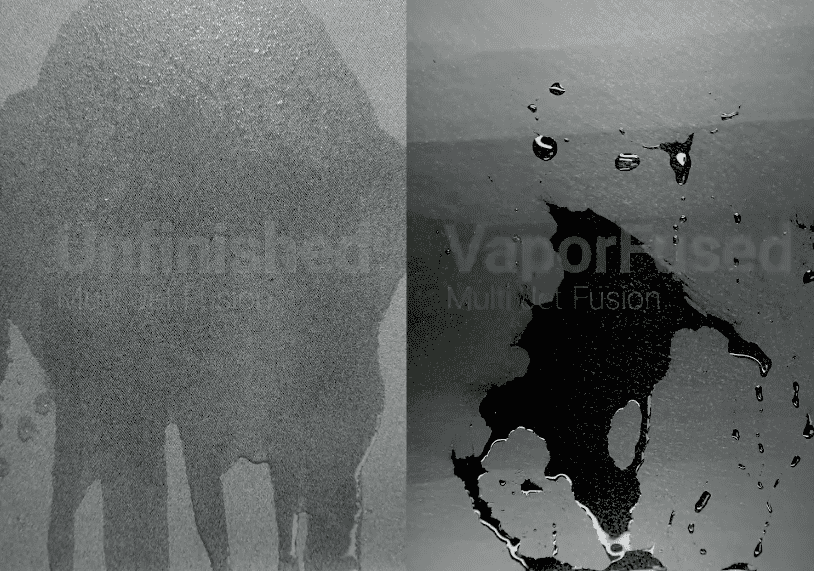

Sealed Surface Water Test Demonstration

Watch as we demonstrate the impact of a sealed surface. We can create a fully sealed, washable part that can be used in a wide variety of high-performance applications.

Vapor Smoothing Water Spray Demonstration

See for yourself how chemical vapor smoothing can transform the surface of a part in this water spray demonstration done by Brian Douglass.

Webinar: Accelerating Innovation with Additive Manufacturing

DI Labs was featured on a Hawk Ridge Systems webinar. Using case studies and behind-the-scenes production tips, we helped companies see how additive manufacturing can help them become more strategic and responsive in the marketplace.

No Further Videos