DI Labs was founded on technical, operational, and quality excellence. From the first day, we set our mission to grow our company with a culture of uncompromising quality. As our company has expanded over the years, we developed and improved our quality management, ERP, and MES systems to maintain our uncompromising quality at scale. Independent certification to ISO 9001:2015 has …

Full-Scale Manufacturing vs. Product Customization

by Carl Douglass, DI Labs President published in the SMW 2023 Additive Industry Report. Full-Scale Manufacturing vs. Product Customization The general belief is that full-scale volume manufacturing and product customization are in direct opposition to one another. That’s because traditional thinking starts with an assumption that to achieve the greatest sales volume and lowest manufacturing cost, products must be designed …

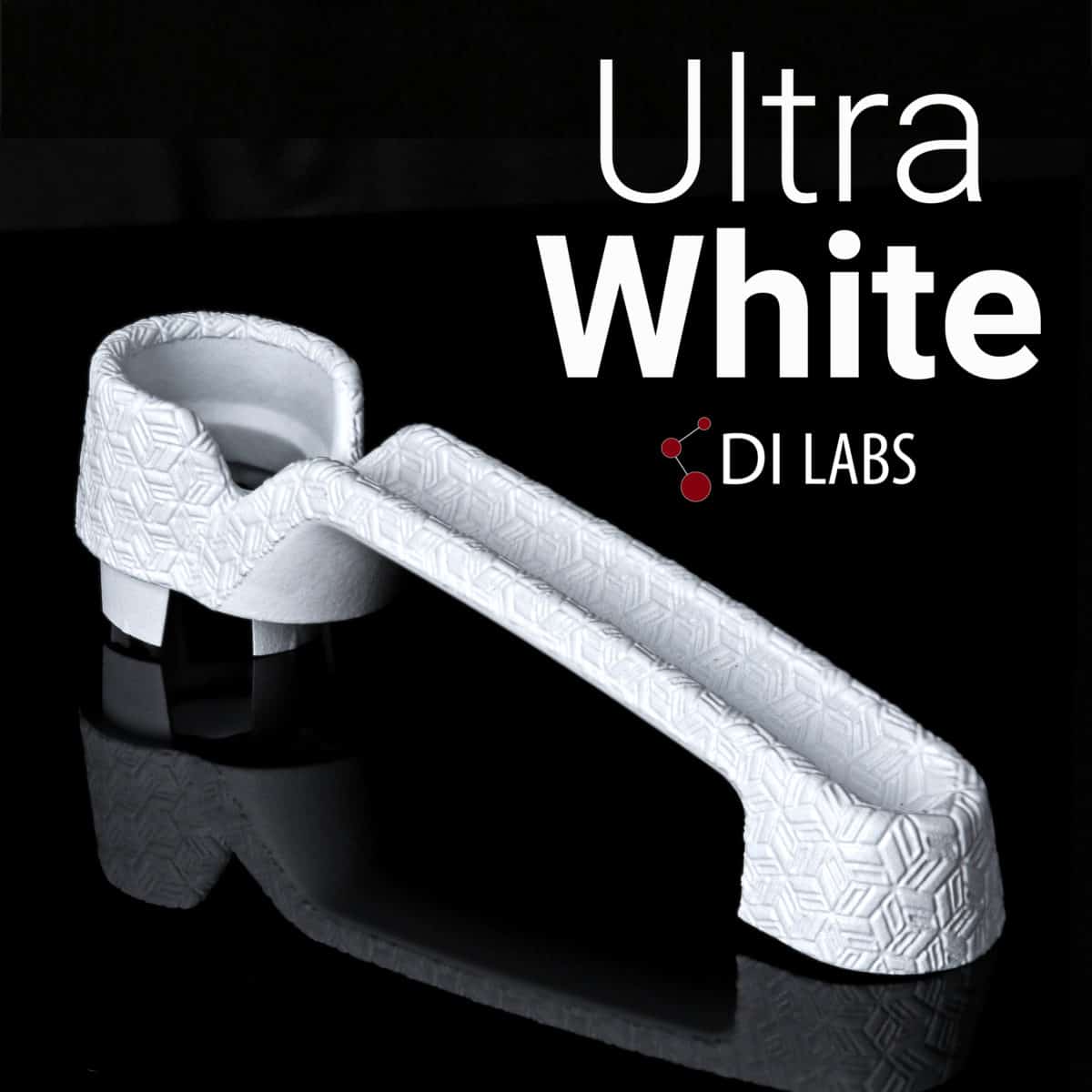

DI Labs Adds Ultra White Printing to Core Capabilities

First in North America to run HP’s Multi Jet Fusion 5420W solution WILLMAR, MN, November 14, 2022: DI Labs continues to help pioneer advancements in additive by being the first North American location to offer HP’s 5420W, a new generation of Multi Jet Fusion (MJF) technology that produces white, industrial-grade nylon parts. For DI Labs, it’s a much-anticipated addition to …

DI Labs is First in the World to “Free the Fortus” as a Stratasys Global Launch Partner for the OpenAM Beta on the Fortus 450MC

WILLMAR, MN, September 16: Stratasys recently named DI Labs a global launch partner for their new OpenAM Software & Validated Materials beta program. Through the beta, DI Labs will be first in the world and the only US location to gain access to the inner workings of the Stratasys Fortus 450MC, an FDM machine that is notorious for having a …

U.S. Senator Tina Smith Tours DI Labs Facility in Willmar, MN

WILLMAR, MN, October 27, 2021: Last week, DI Labs hosted a facility tour for a group that included U.S. Senator Tina Smith. It was organized by Sarah Swedburg, Business Development Manager for the Kandiyohi County and City of Willmar Economic Development Commission. Senator Smith was in Willmar to attend a roundtable discussion about broadband expansion in Kandiyohi County.

Swiss Company, Kowch, Selects DI Labs as Exclusive North American Production Partner

October 21, 2020: The COVID-19 global pandemic has triggered an urgent need for innovation on a scale exponentially larger and faster than ever before. DI Labs is a leader in the additive manufacturing industry and has experienced how instrumental additive technologies have been in solving critical problems created by the pandemic, such as supply chain breakdowns, accelerated product prototyping, and expedited production for finished products.

DI Labs to Reveal the Future of Product Innovation During Live Stream Event

July 16, 2020: DI Labs is driven by a singular philosophy – invest early and often to meet the emerging needs of the market, even if it’s risky. That approach has placed them on the front lines of digital manufacturing innovation and equipped them to solve some of today’s most urgent and impactful challenges, including medical equipment shortages caused by COVID-19.

DI Labs Expands Finishing Capabilities with AMT’s patented PostPro3D® Technology

July 13, 2020: Fueled by the needs of the market, DI Labs has made a bold move with the addition of an AMT PostPro3D® machine. It’s an automated post-processing system that can create smooth, sealed, sanitizable surfaces on parts printed with a wide variety of polymer-based technologies including HP Multi Jet Fusion and Fused Filament Fabrication. The results rival the quality and consistency of injection molding.

Free Webinar: Accelerating Innovation with Additive Manufacturing

Friday, April 24, 2020: As the nation’s critical need for PPE escalates, DI Labs is intensely focused on innovating and testing design concepts for key items such as N95 masks. They are motivated by a desire to help but also by a concern for the safety offered by 3D printed solutions that are currently being circulated for use by our healthcare workers.

DI Labs Innovates to Elevate PPE Safety for Healthcare Professionals

Friday, April 24, 2020: As the nation’s critical need for PPE escalates, DI Labs is intensely focused on innovating and testing design concepts for key items such as N95 masks. They are motivated by a desire to help but also by a concern for the safety offered by 3D printed solutions that are currently being circulated for use by our healthcare workers.

- Page 1 of 2

- 1

- 2