Finishing Options

Finishing: Reference & Compare

We offer a full spectrum of finishing options and are running some of the industry's most cutting edge finishing technologies.

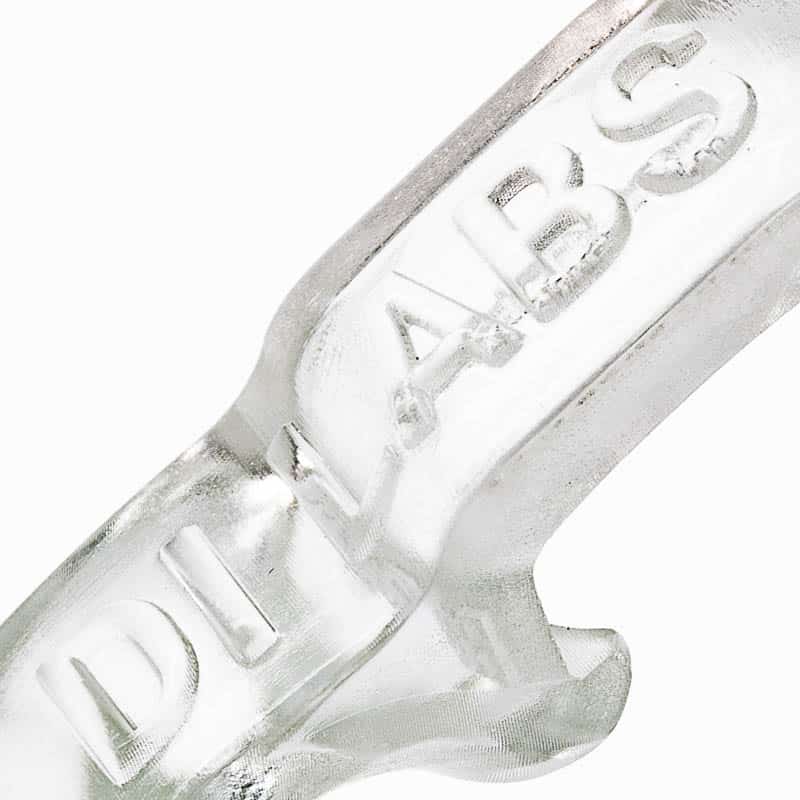

Vapor Smoothing

Description:

Smooths and seals surfaces to achieve an injection molded look and feel

| Advantages |

|

| Compatible Materials |

Nylon PA12 Nylon PA 11 Nylon PA12 Glass Bead Reinforced Nylon PA12 Full Color Continuous Fiber Carbon Fiber Continuous Fiber Fiberglass Continuous Fiber HSHT Fiberglass Continuous Aramid Fiber (Kevlar®) Onyx Nylon 6 |

| Special Considerations |

|

| Gallery | View |

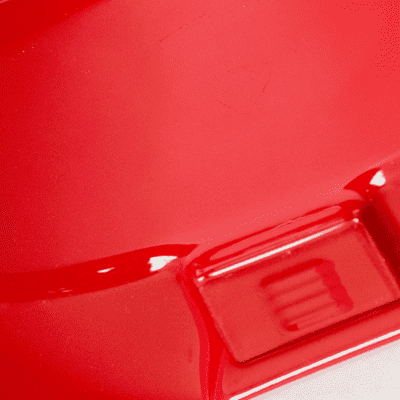

Dye Coloring

Description:

Available colors - yellow, orange, red, green, blue, purple, black

| Advantages |

|

| Compatible Materials |

Nylon PA12 Nylon PA 11 Elastomeric Polyurethane - EPU 41 Nylon PA12 Glass Bead Reinforced Nylon PA12 Full Color Lubrizol Estane Thermoplastic Polyurethane - TPU Henkel Loctite IND 405 Clear |

| Special Considerations |

|

| Gallery | View |

Standard Finish

Description:

After parts are post-processed, they have a standard finish that varies in color and texture depending on the technology.

| Advantages |

|

| Compatible Materials |

Dental Prototype Resin - DPR 10 Elastomeric Polyurethane - EPU 40 Elastomeric Polyurethane - EPU 41 Epoxy Resin - EPX 82 Flexible Polyurethane - FPU 50 Henkel Loctite IND 405 Clear High Temp Rigid - Cyanate Ester - CE 221 Multi-Purpose Polyurethane - MPU 100 Prototype Resin - PR 25 Rigid Polyurethane - RPU 130 Rigid Polyurethane - RPU 70 Silicon - SIL 30 Urethane Methacrylate - UMA 90 |

| Special Considerations |

|

| Gallery | View |

No Further Finishing

| Surface Finishing | Description | Advantages | Compatible Materials | Special Considerations | Gallery | |

|---|---|---|---|---|---|---|

|

Smooths and seals surfaces to achieve an injection molded look and feel |

|

|

View | |||

|

Available colors - yellow, orange, red, green, blue, purple, black |

|

|

View | |||

|

After parts are post-processed, they have a standard finish that varies in color and texture depending on the technology. |

|

Dental Prototype Resin - DPR 10,

Elastomeric Polyurethane - EPU 40,

Elastomeric Polyurethane - EPU 41,

Epoxy Resin - EPX 82,

Flexible Polyurethane - FPU 50,

Henkel Loctite IND 405 Clear,

High Temp Rigid - Cyanate Ester - CE 221,

Multi-Purpose Polyurethane - MPU 100,

Prototype Resin - PR 25,

Rigid Polyurethane - RPU 130,

Rigid Polyurethane - RPU 70,

Silicon - SIL 30,

Urethane Methacrylate - UMA 90,

|

|

View | ||

|

Makes parts clear enough to see color through |

|

|

View | |||

|

Painting is possible on large volume orders of 3D printed parts |

|

|

||||

|

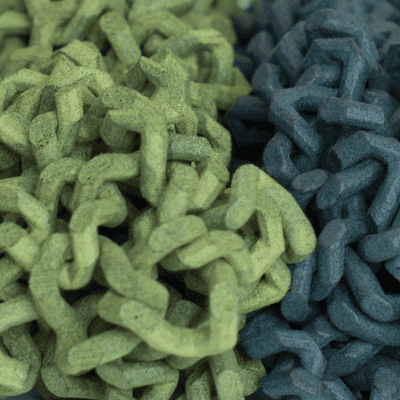

A chemical-free post-processing step for color part production |

|

|

View |

Get a quote or request help

The right finishing technique can be the secret sauce to your project's success. Contact DI Labs to get an instant quote that includes finishing or request our help to determine the right finishing option for your needs.