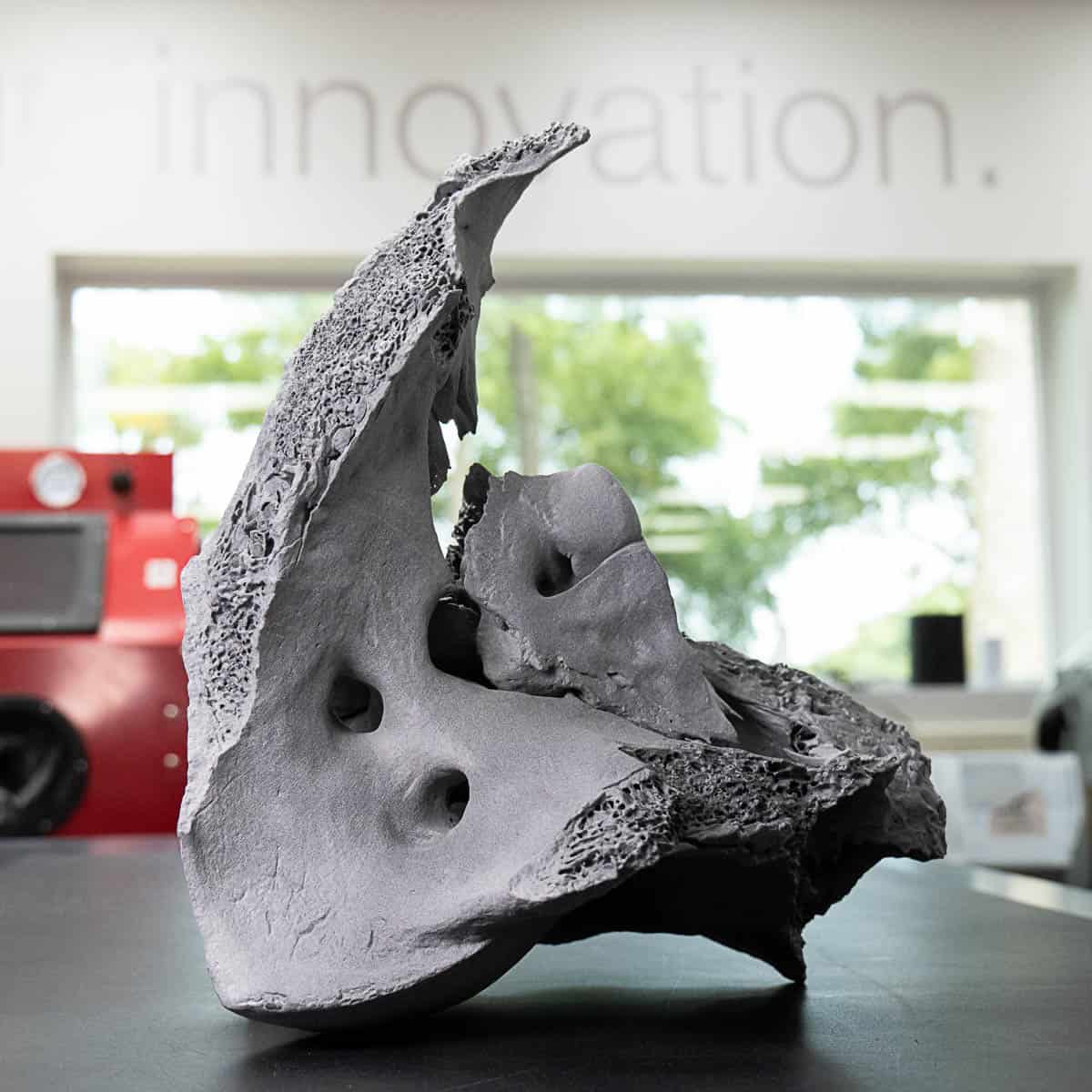

Nylon PA12

Nylon Polyamide (PA) 12 is a strong, durable material that provides production-grade accuracy and dimensional consistency. Jet Fusion PA12 is ideal for functional prototypes and end-use parts because finished parts are fully dense, isotropic, and offer mechanical properties similar to injection molded Nylon. PA12 is ideally suited to medical devices, consumer goods, industrial, aerospace, and automotive applications because of its excellent surface finish and the ability to dye or vapor smooth its surfaces for smooth, sealed surfaces similar to molded parts. With HP Multi Jet Fusion, production volumes in the tens of thousands are possible due to the quick printing and viable economics.

Download Specs

- Robust thermoplastic produces high-density parts with balanced property profiles and strong structures.

- Provides excellent chemical resistance to oils, greases, aliphatic hydrocarbons, and alkalies.

- Ideal for complex assemblies, housings, enclosures, and watertight applications.

- Biocompatibility certifications - meets USP Class I-VI and US FDA guidance for Intact Skin Surface Devices.3

- Designed for the production of functional parts across a variety of industries.

- Provides the best balance between performance and reusability.

- Achieves watertight properties without any additional post-processing.

- Engineered to produce final parts and functional prototypes with fine detail and dimensional accuracy.

Flexural Modulus

(ASTM D790)

- 1730 Mpa

- 251 Ksi

Flexural Strength

(ASTM D790)

- 65 Mpa

- 9.425 Ksi

Tensile Modulus

(ASTM D638)

- 1700 Mpa

- 247 Ksi

UTS

(ASTM D638)

- 48 Mpa

- 6.96 Ksi

Impact Resistance - Notched Izod

(ASTM D256 Method B)

- 3.5 KJ/M2

- 3.33 FT-LB/IN2

Heat Deflection - Temperature

(0.455 MPa (66 Psi), ASTM D648)

- 175 °C

- 347 °F

Heat Deflection - Temperature

(1.82 MPa (264 Psi), ASTM D648)

- 95 °C

- 203 °F

Hardness

(ASTM D2240)

- 80 Shore D

Density

- 1.01 (G/Cm3)