Medical Device Innovation Acceleration

Accelerated Digital Manufacturing Built for Class I, II, & III Medical Devices

DI Labs enables fast, safe, and compliant development through on-demand digital manufacturing. Our platform empowers teams to move from concept to clinical trials and commercialization – without tooling, without compromise.

Use Cases for Digital Manufacturing Through the Development Cycle

1. Concept & Strategy

- Concept mock ups

- Early prototypes

- Show & tell models

- Functional prototypes

- Idea validation

- Design of experiment models

- Functional prototypes

- Design validation

- DOE models

- Benchtop models

- Repeatable production

- Human factors optimization models

- On-demand production

- Responsive design updates

- Regulatory-ready documentation

- Bridge production

- Permanent low-volume production

- Post-launch design improvements (Class I Devices)

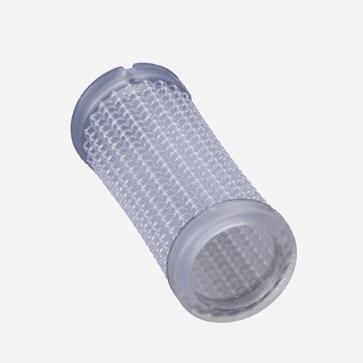

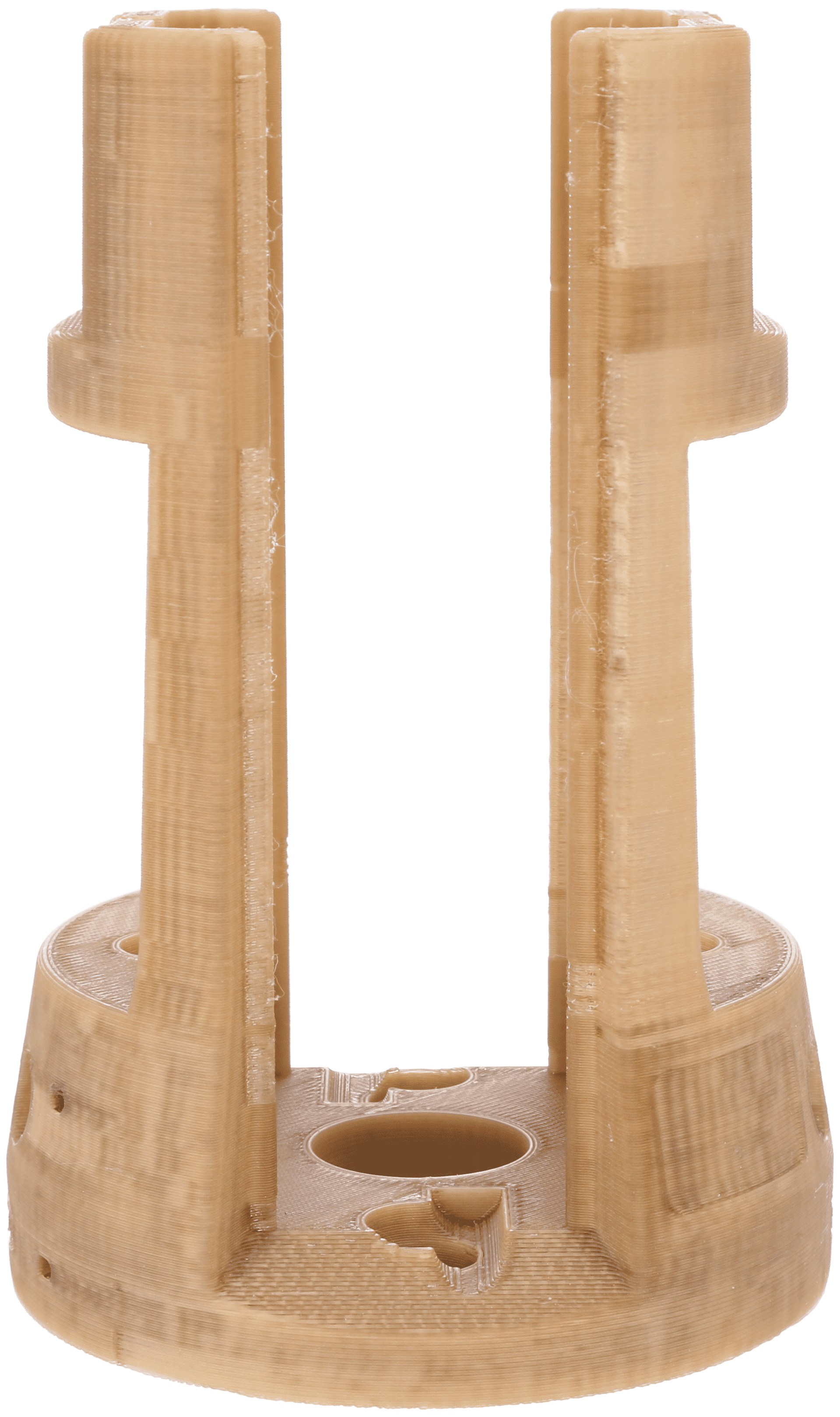

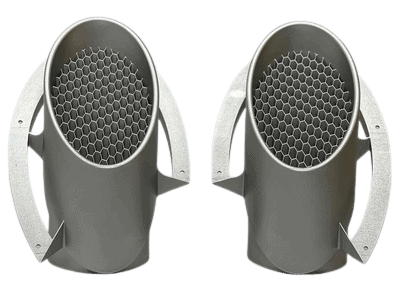

Example Housing & Assembly:

Supported Applications:

- Minimally Invasive Surgical Devices

- Cardiovascular Delivery and Retrieval Systems

- Medical Robotic Components

- Medical Device Housings & Assemblies

- Robotic End Effectors

Client Testimonials:

Traditional Pain vs Accelerated Digital Solutions

Expensive, design-locked tooling

An injection mold alternative with no expensive tooling and unlimited iteration freedom

Long lead times for small batches

On-demand, agile production & rapid responsiveness for clinical trial builds

Intense regulatory requirements

Regulatory compliance with ISO 10993 biocompatible materials, locked processes and lot-level power-to-part tracking

Design iteration is slow and expensive

Unlocked iteration for rapid integration of clinical feedback, interface optimization & efficacy improvements

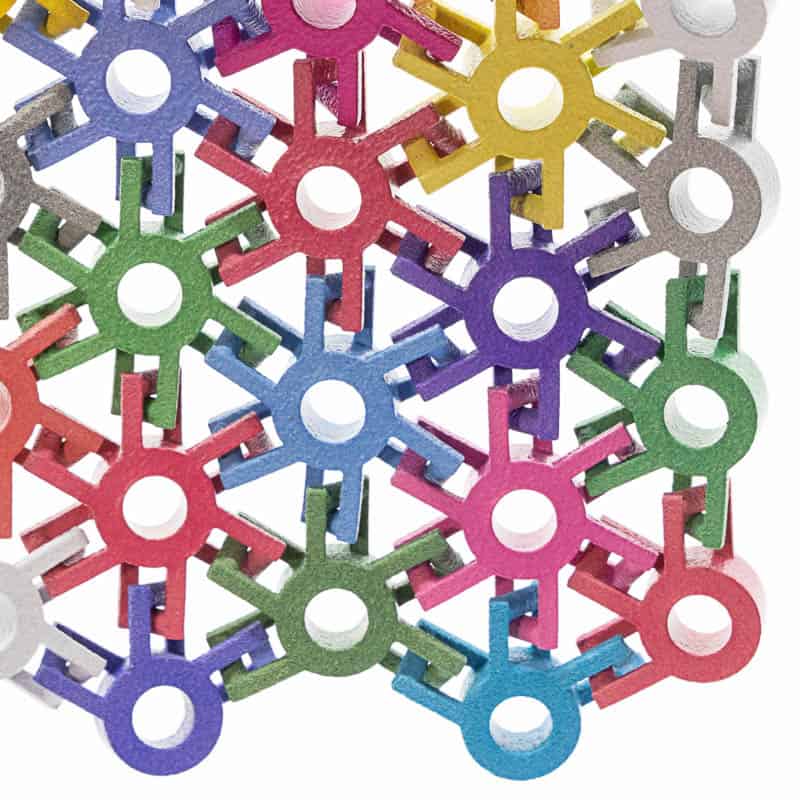

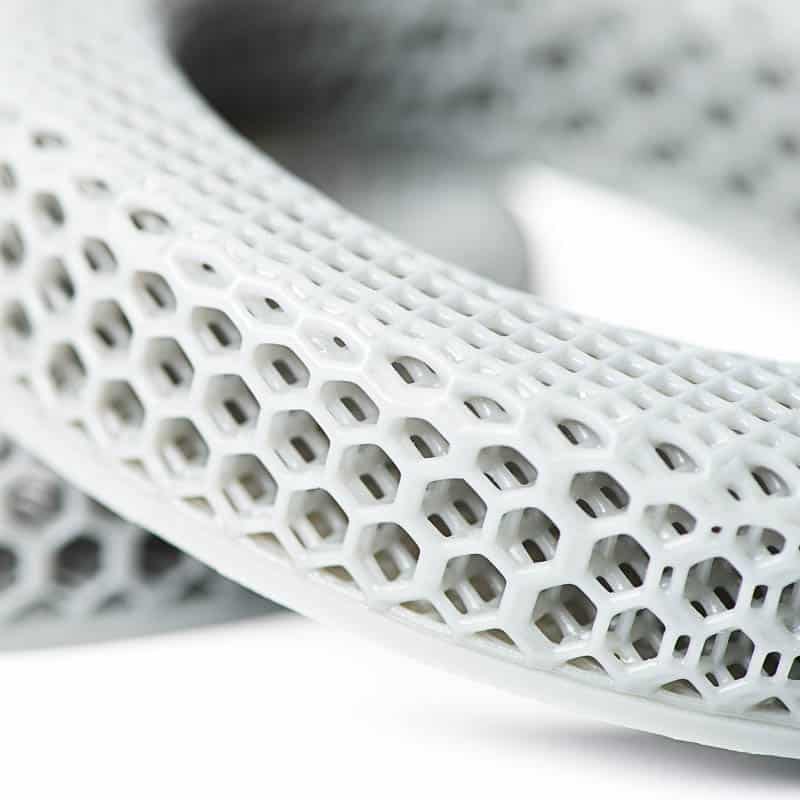

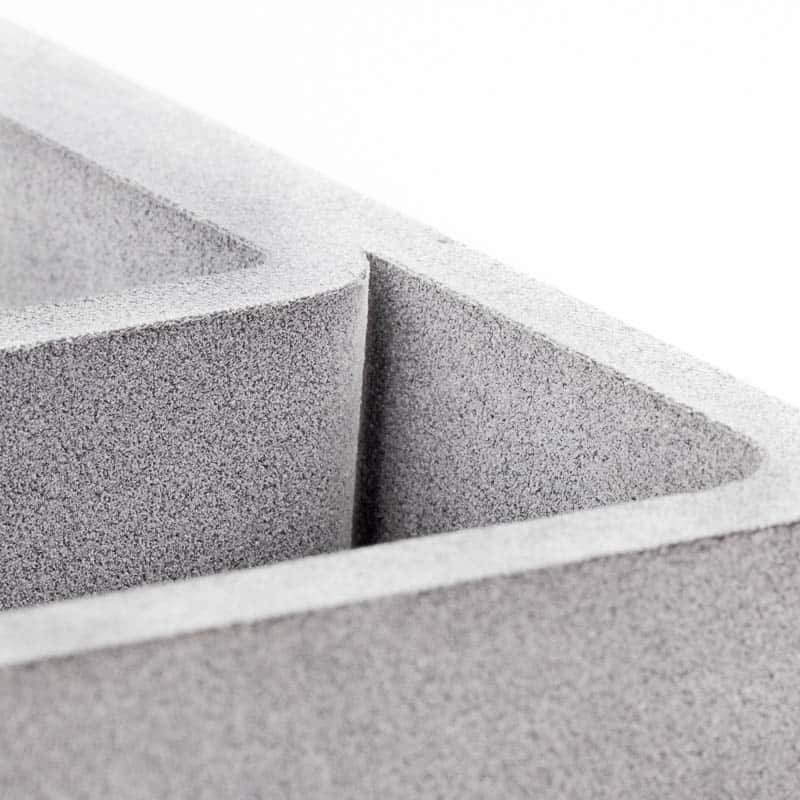

Biocompatible Materials

| Title | Type of Material | Stiffness | Ultimate Strength | High Temperature Capability | Ductility | Impact Resistance | Gallery | Technical Document | |

|---|---|---|---|---|---|---|---|---|---|

| Elastomer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Elastomer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Elastomer | View |

Download |

|||||||

| Polymer | View | ||||||||

| Polymer | View |

Download |

|||||||

| Metal | View | ||||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Elastomer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

Learn More:

Reach out to us for support or more information!

[email protected] | 320-403-9483

"*" indicates required fields