Class I, II & III Medical Device Manufacturing

An Injection Mold Alternative for Medical Device Manufacturing

DI Labs enables accelerated, compliant medical device development from concept to commercialization using digital manufacturing. Our advanced additive manufacturing technologies and highly controlled digital workflows empower teams to move quickly and efficiently through each development phase with unlimited design iteration and injection-mold-quality parts from concept to commercialization.

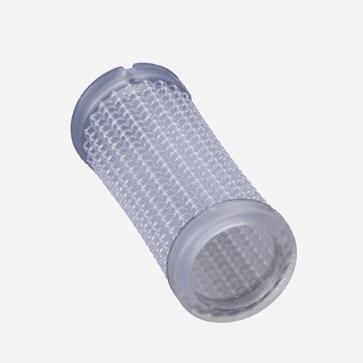

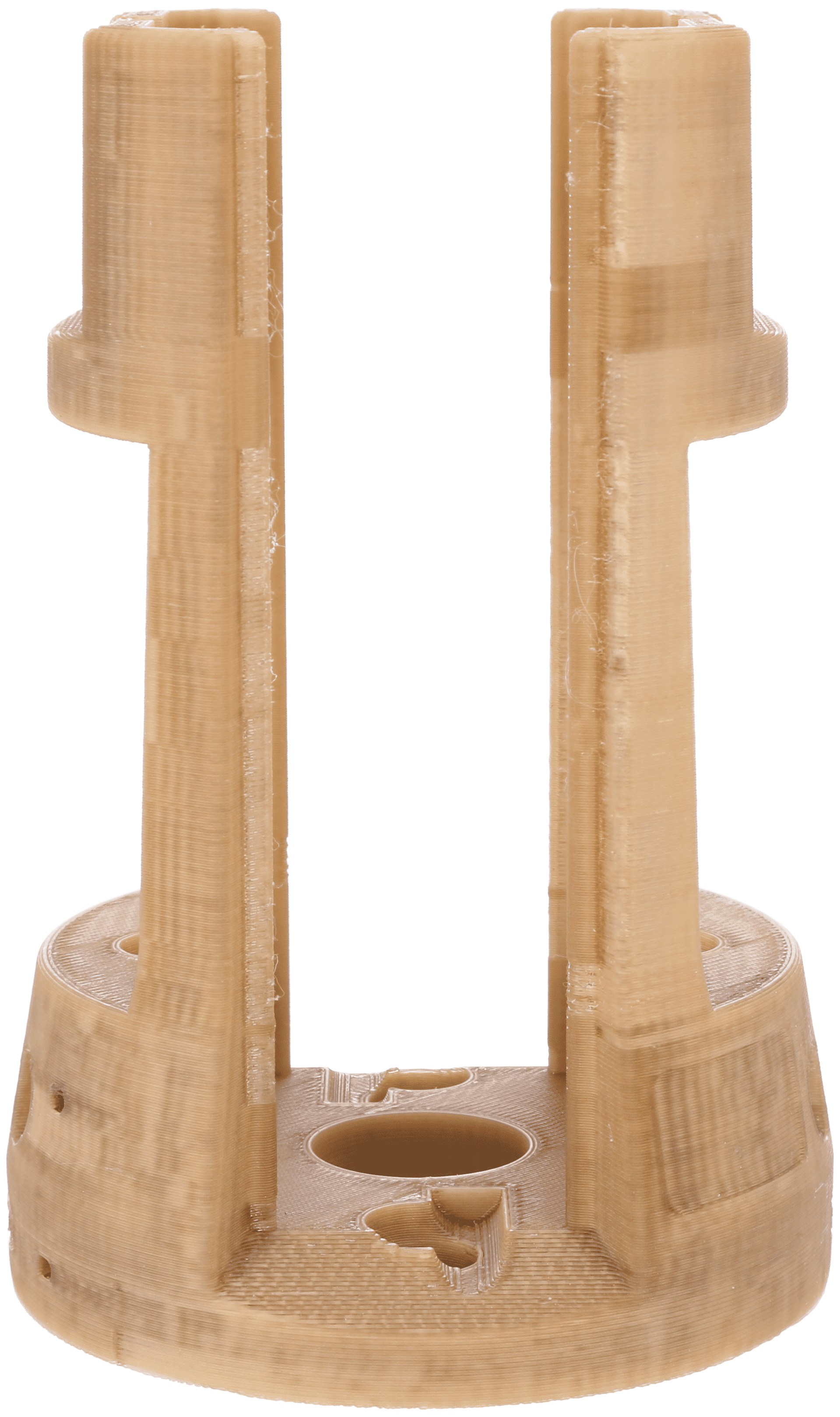

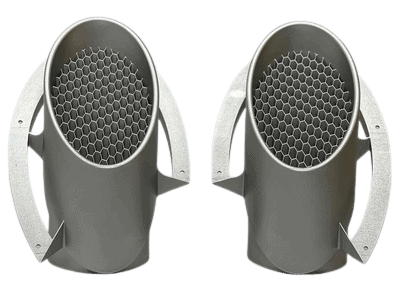

Example Medical Device Applications:

- Minimally Invasive Surgical Devices

- Cardiovascular Delivery and Retrieval Systems

- Medical Robotic Components

- Medical Device Housings & Assemblies

- Robotic End Effectors

DI Labs Additive Manufacturing vs Injection Molding

Biocompatible

Materials

DI Labs

Wide variety of biocompatible materials including polymers, elastomers & metals

Injection Molding

Wide variety of biocompatible materials including polymers, elastomers & metals

Tool-Free

Manufacturing

DI Labs

No tooling required, eliminating capital expense & long wait times

Injection Molding

Tooling required with significant capital expense & long wait times

On-Demand Batch Production

DI Labs

Short lead times to support acceleration through testing & clinical trials

Injection Molding

Long lead times for mold changes through testing & trials

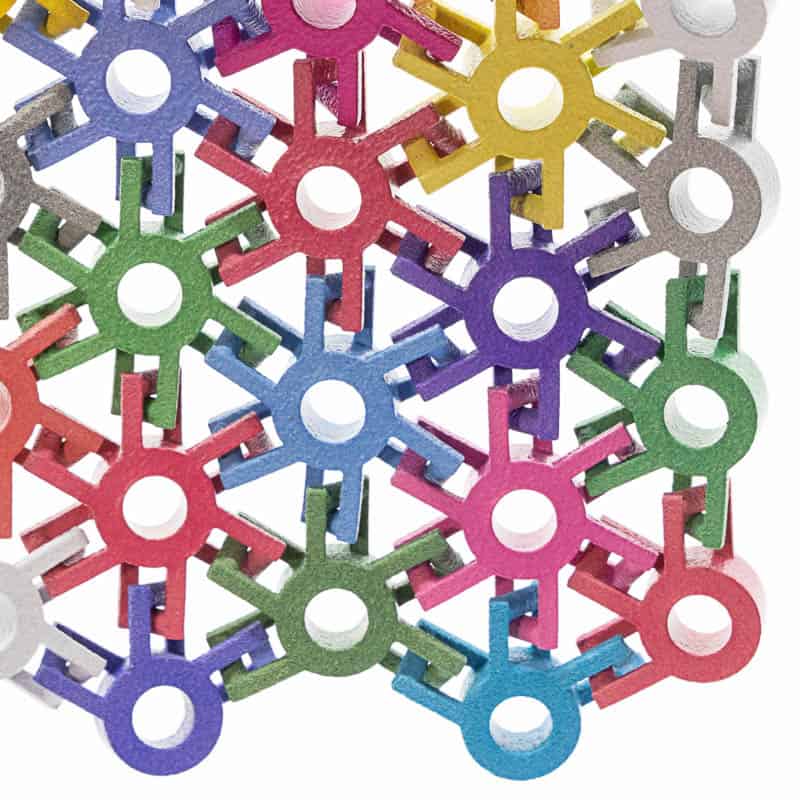

Unlimited

Design Iteration

DI Labs

Tool-free enables responsive design iteration based on user feedback

Injection Molding

Expensive, design-locked tooling limits responsiveness & abilty to iterate

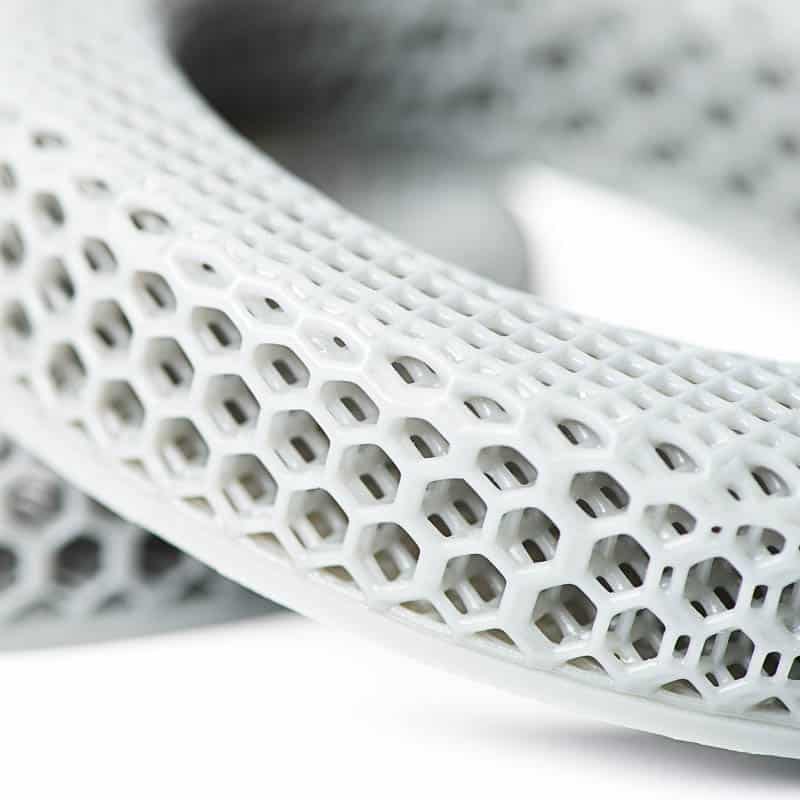

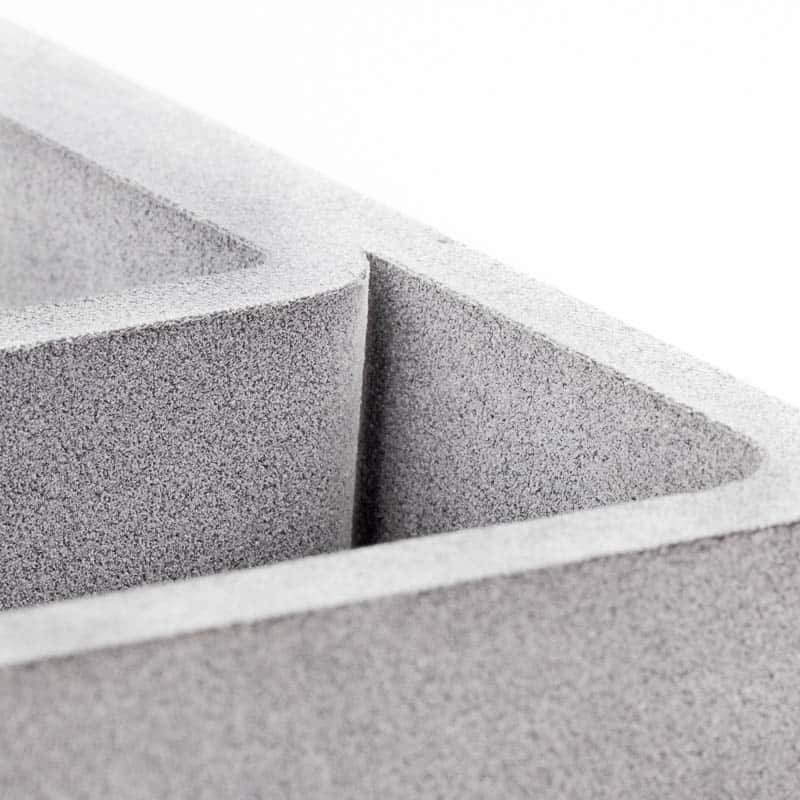

Our Biocompatible Materials

We offer a wide range of biocompatible materials – including polymers, elastomers, and metals – to serve a full spectrum of Class I, II, & III medical device applications. See our biocompatible materials table for more details.

Medical Device Housing & Assembly: Benefits of Additive Manufacturing

Use Cases for Additive Manufacturing Through the Medical Device Development Cycle

Concept & Strategy

- Concept mock ups

- Early prototypes

- Show & tell models

- Functional prototypes

- Idea validation

- Design of experiment models

- Functional prototypes

- Design validation

- DOE models

- Benchtop models

- Repeatable production

- Human factors optimization models

- On-demand production

- Responsive design updates

- Regulatory-ready documentation

- Bridge production

- Permanent low-volume prod.

- Post-launch improvements (Class I Devices)

Biocompatible Materials Table

| Title | Type of Material | Stiffness | Ultimate Strength | High Temperature Capability | Ductility | Impact Resistance | Gallery | Technical Document | |

|---|---|---|---|---|---|---|---|---|---|

| Elastomer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Elastomer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Elastomer | View |

Download |

|||||||

| Polymer | View | ||||||||

| Polymer | View |

Download |

|||||||

| Metal | View | ||||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Elastomer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

|||||||

| Polymer | View |

Download |

What Medical Device Teams Really Want to Know About Additive

The questions following DI Labs’ technical session at MD&M West 2026 reflected a noticeable shift in how medical device teams are thinking about additive manufacturing. DI Labs CEO Carl Douglass delivered the session, which provided a deep dive into the realities of using additive manufacturing within regulated medical device programs. See the detailed Q&A in our LinkedIn newsletter.

Solutionology Stories Podcast Episodes From DI Labs

Example Medical Device Projects

Reach out for support or more information!

[email protected] | 320-403-9483

"*" indicates required fields

DI Labs Client Testimonials

Contact Us Directly