First in North America to run HP’s Multi Jet Fusion 5420W solution

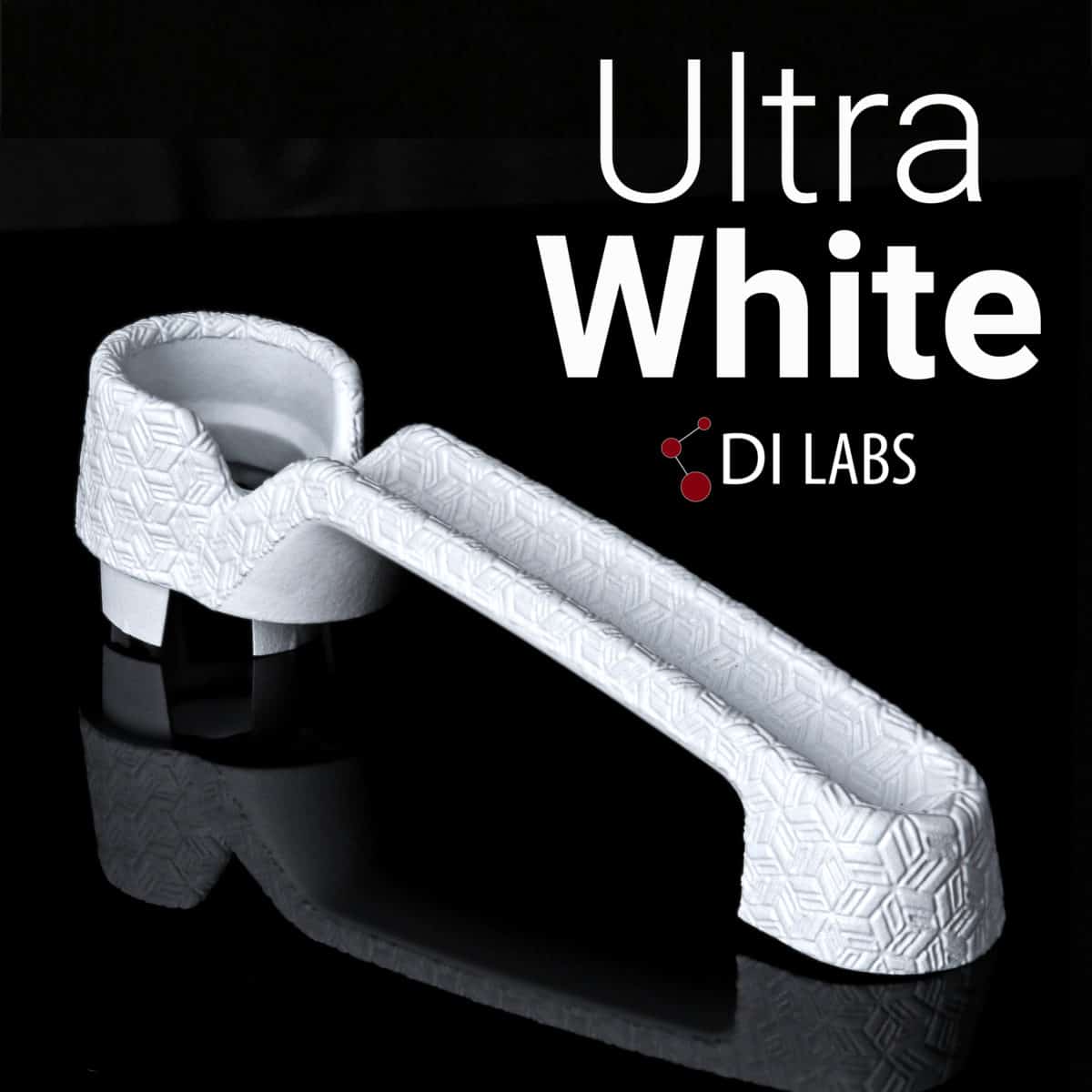

“We’ve run over a thousand parts on the 5420W and could not be more pleased with the surface quality, consistency, and color. We’re calling them Ultra White because this ground-breaking technology prints industrial-quality nylon parts that hold their brilliant white color, have the resolution for intricate textures, and can be sealed for easy cleaning,” explains DI Labs CEO, Carl Douglass. He adds, “DI Labs serves a large number of medical device clients and has been pushing HP for a white production solution for several years. Now we have another valuable tool in our toolbox for high-end applications where white parts are an essential aesthetic.”

The new MJF technology they use for Ultra White perfectly complements DI Labs’ current fleet of MJF printers for dyeable grey and full-color production. “MJF technology is the workhorse of our operation. It is incredibly consistent and reliable, making full-scale manufacturing possible in many applications. The addition of Ultra White opens a whole new set of doors for our clients.” adds Brian Douglass, DI Labs COO.

This new Ultra White addition serves clients in conjunction with their proprietary texturing process and product development capabilities. Other capability advancements at DI Labs include the addition of metrology-grade 3D scanning CMM for non-contact, high-accuracy analysis to support their quality control and quality assurance processes. They’ve also been a first-in-the-world beta site for the Stratasys 450MC OpenAM, allowing them to use highly engineered materials for FDM production manufacturing.

DI Labs is located in Minnesota and was founded by a team of product development engineers. Owners and brothers Carl, Brian, and Sean Douglass have created a unique company culture founded on “solutionology” allowing them to defy the odds and build one of the country’s most respected additive manufacturing service bureaus.

For more information about DI Labs: website | youtube | linkedin