Materials

Materials: Reference & Compare

We can run an ever-growing list of materials including polymers, elastomers, metals and composites. Their unique properties will impact performance and determine whether they are the right fit for your project or part.

BioMed Elastic 50A Resin – SLA

Type of Material: Elastomer

| Color | |

| Stiffness | |

| Ultimate Strength | |

| High Temperature Capability | |

| Ductility | |

| Impact Resistance | |

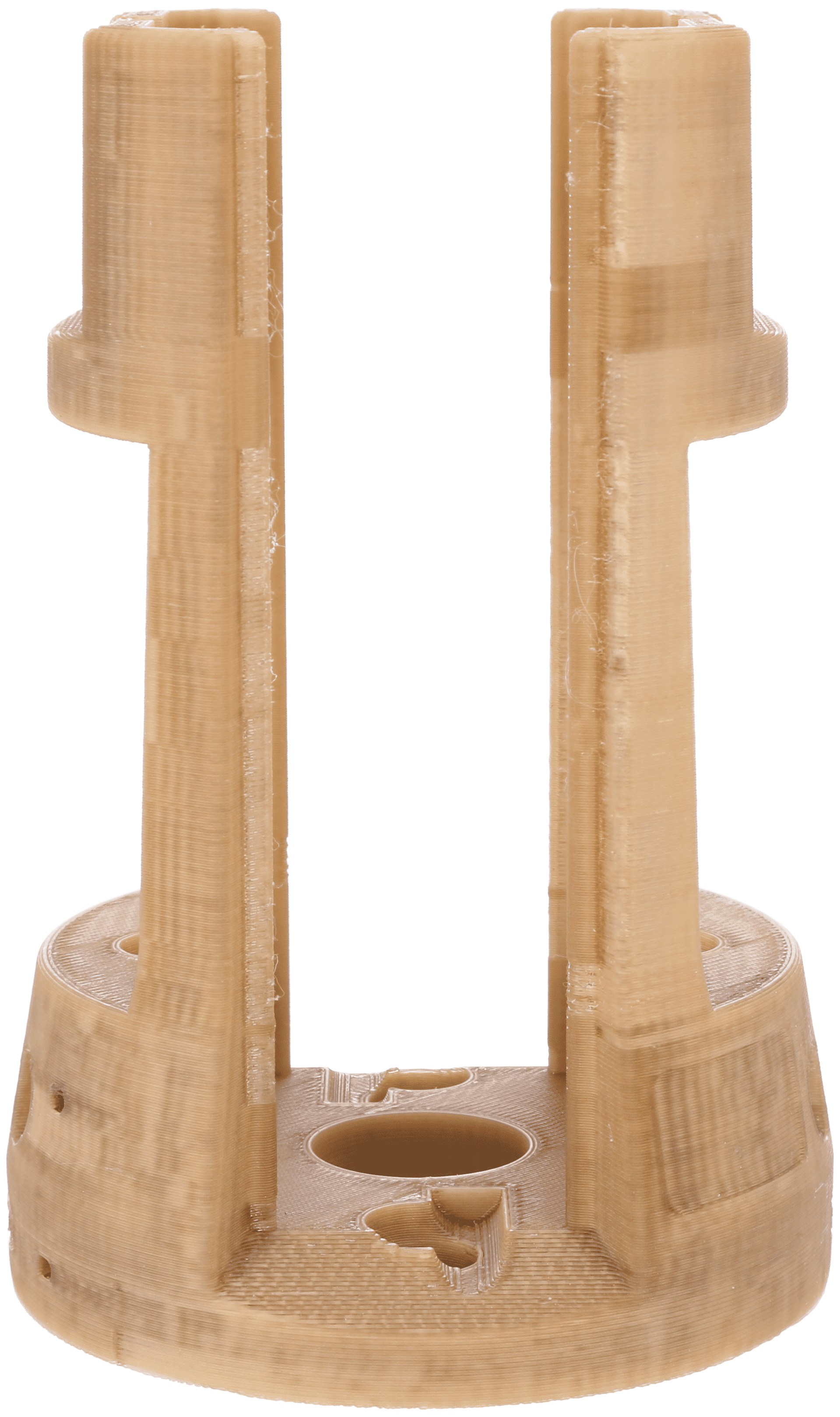

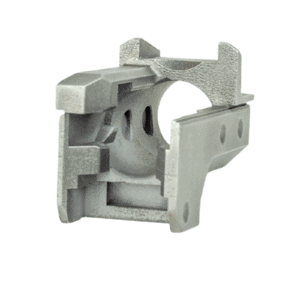

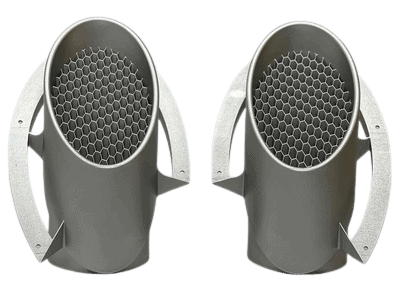

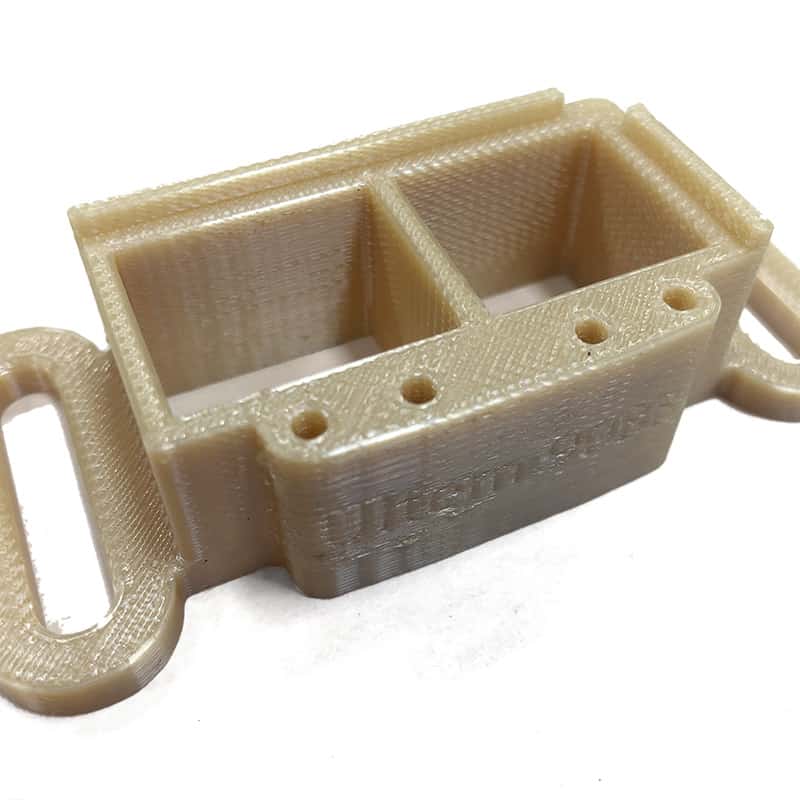

| Gallery | |

| Document |

Download |

BioMed Durable Resin – SLA

Type of Material: Polymer

| Color | |

| Stiffness | |

| Ultimate Strength | |

| High Temperature Capability | |

| Ductility | |

| Impact Resistance | |

| Gallery | |

| Document |

Download |

BioMed Flexible 80A Resin – SLA

Type of Material: Elastomer

| Color | |

| Stiffness | |

| Ultimate Strength | |

| High Temperature Capability | |

| Ductility | |

| Impact Resistance | |

| Gallery | |

| Document |

Download |

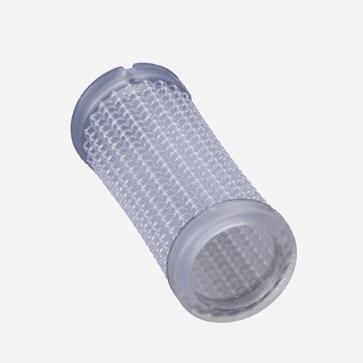

BioMed Clear Resin – SLA

Type of Material: Polymer

| Color | |

| Stiffness | |

| Ultimate Strength | |

| High Temperature Capability | |

| Ductility | |

| Impact Resistance | |

| Gallery | |

| Document |

Download |

BioMed Black Resin – SLA

Type of Material: Elastomer

| Color | |

| Stiffness | |

| Ultimate Strength | |

| High Temperature Capability | |

| Ductility | |

| Impact Resistance | |

| Gallery | |

| Document |

Download |

No Further Materials

BioMed Elastic 50A Resin – SLA

Type of Material: Elastomer

| Color | |

| Flexural Modulus (ASTM D790) |

|

| Tensile Strength (ASTM D638) |

|

| Elongation At Break | |

| Gallery | |

| Document |

Download |

BioMed Durable Resin – SLA

Type of Material: Polymer

| Color | |

| Flexural Modulus (ASTM D790) |

643Mpa 94.1Ksi |

| Tensile Strength (ASTM D638) |

24Mpa 3.42Ksi |

| Elongation At Break | |

| Gallery | |

| Document |

Download |

BioMed Flexible 80A Resin – SLA

Type of Material: Elastomer

| Color | |

| Flexural Modulus (ASTM D790) |

|

| Tensile Strength (ASTM D638) |

|

| Elongation At Break | |

| Gallery | |

| Document |

Download |

BioMed Clear Resin – SLA

Type of Material: Polymer

| Color | |

| Flexural Modulus (ASTM D790) |

2300Mpa 322Ksi |

| Tensile Strength (ASTM D638) |

84Mpa 12.2Ksi |

| Elongation At Break | |

| Gallery | |

| Document |

Download |

BioMed Black Resin – SLA

Type of Material: Elastomer

| Color | |

| Flexural Modulus (ASTM D790) |

1668.53Mpa 242Ksi |

| Tensile Strength (ASTM D638) |

|

| Elongation At Break | |

| Gallery | |

| Document |

Download |

No Further Materials

BioMed Elastic 50A Resin – SLA

Type of Material: Elastomer

| Color | |

| Flexural Modulus (ASTM D790) |

|

| Flexural Strength (ASTM D790) |

|

| Tensile Modulus (ASTM D638) |

|

| Yield Strength (ASTM D638 (Polymer), ASTM E9 (Metal)) |

|

| UTS (ASTM D638) |

2.32Mpa .468Ksi |

| Elongation at Break | |

| Impact Resistance Notched Izod (ASTM D256 Method A) |

|

| Impact Resistance Notched Izod (ASTM D256 Method B) |

|

| Heat Deflection - Temperature (0.455 MPa (66 Psi), ASTM D648) |

|

| Heat Deflection - Temperature (1.82 MPa (264 Psi), ASTM D648) |

|

| Hardness (ASTM E18) Rockwell HRC |

|

| Hardness (ASTM D2240) Shore D |

|

| Hardness (ASTM D2240) Shore A |

50 |

| Density (G/Cm3) |

|

| Density (Relative) |

|

| Gallery | |

| Document |

Download |

BioMed Durable Resin – SLA

Type of Material: Polymer

| Color | |

| Flexural Modulus (ASTM D790) |

643Mpa 94.1Ksi |

| Flexural Strength (ASTM D790) |

24Mpa 3.42Ksi |

| Tensile Modulus (ASTM D638) |

994Mpa 149Ksi |

| Yield Strength (ASTM D638 (Polymer), ASTM E9 (Metal)) |

|

| UTS (ASTM D638) |

29.1Mpa |

| Elongation at Break | |

| Impact Resistance Notched Izod (ASTM D256 Method A) |

114J/M 2.13Ft-Lb/In |

| Impact Resistance Notched Izod (ASTM D256 Method B) |

98KJ/M2 1.84Ft-Lb/In2 |

| Heat Deflection - Temperature (0.455 MPa (66 Psi), ASTM D648) |

46°C 115°F |

| Heat Deflection - Temperature (1.82 MPa (264 Psi), ASTM D648) |

40°C 104°F |

| Hardness (ASTM E18) Rockwell HRC |

|

| Hardness (ASTM D2240) Shore D |

75 |

| Hardness (ASTM D2240) Shore A |

|

| Density (G/Cm3) |

|

| Density (Relative) |

|

| Gallery | |

| Document |

Download |

BioMed Flexible 80A Resin – SLA

Type of Material: Elastomer

| Color | |

| Flexural Modulus (ASTM D790) |

|

| Flexural Strength (ASTM D790) |

|

| Tensile Modulus (ASTM D638) |

|

| Yield Strength (ASTM D638 (Polymer), ASTM E9 (Metal)) |

|

| UTS (ASTM D638) |

8.9Mpa 1.29Ksi |

| Elongation at Break | |

| Impact Resistance Notched Izod (ASTM D256 Method A) |

|

| Impact Resistance Notched Izod (ASTM D256 Method B) |

|

| Heat Deflection - Temperature (0.455 MPa (66 Psi), ASTM D648) |

|

| Heat Deflection - Temperature (1.82 MPa (264 Psi), ASTM D648) |

|

| Hardness (ASTM E18) Rockwell HRC |

|

| Hardness (ASTM D2240) Shore D |

|

| Hardness (ASTM D2240) Shore A |

80 |

| Density (G/Cm3) |

|

| Density (Relative) |

|

| Gallery | |

| Document |

Download |

BioMed Clear Resin – SLA

Type of Material: Polymer

| Color | |

| Flexural Modulus (ASTM D790) |

2300Mpa 322Ksi |

| Flexural Strength (ASTM D790) |

84Mpa 12.2Ksi |

| Tensile Modulus (ASTM D638) |

|

| Yield Strength (ASTM D638 (Polymer), ASTM E9 (Metal)) |

|

| UTS (ASTM D638) |

52Mpa 7.5Ksi |

| Elongation at Break | |

| Impact Resistance Notched Izod (ASTM D256 Method A) |

35J/M 0.658Ft-Lb/In |

| Impact Resistance Notched Izod (ASTM D256 Method B) |

|

| Heat Deflection - Temperature (0.455 MPa (66 Psi), ASTM D648) |

67°C 152°F |

| Heat Deflection - Temperature (1.82 MPa (264 Psi), ASTM D648) |

54°C 129°F |

| Hardness (ASTM E18) Rockwell HRC |

|

| Hardness (ASTM D2240) Shore D |

78 |

| Hardness (ASTM D2240) Shore A |

|

| Density (G/Cm3) |

|

| Density (Relative) |

|

| Gallery | |

| Document |

Download |

BioMed Black Resin – SLA

Type of Material: Elastomer

| Color | |

| Flexural Modulus (ASTM D790) |

1668.53Mpa 242Ksi |

| Flexural Strength (ASTM D790) |

|

| Tensile Modulus (ASTM D638) |

|

| Yield Strength (ASTM D638 (Polymer), ASTM E9 (Metal)) |

|

| UTS (ASTM D638) |

35.71Mpa 5.18Ksi |

| Elongation at Break | |

| Impact Resistance Notched Izod (ASTM D256 Method A) |

24.77J/M 0.464Ft-Lb/In |

| Impact Resistance Notched Izod (ASTM D256 Method B) |

|

| Heat Deflection - Temperature (0.455 MPa (66 Psi), ASTM D648) |

67.9°C 154°F |

| Heat Deflection - Temperature (1.82 MPa (264 Psi), ASTM D648) |

49.4°C 121°F |

| Hardness (ASTM E18) Rockwell HRC |

|

| Hardness (ASTM D2240) Shore D |

77 |

| Hardness (ASTM D2240) Shore A |

|

| Density (G/Cm3) |

|

| Density (Relative) |

|

| Gallery | |

| Document |

Download |

No Further Materials

| Title | Type of Material | Color | Biocompatibility | Stiffness | Ultimate Strength | High Temperature Capability | Ductility | Impact Resistance | Gallery | Technical Document | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Elastomer | ✔ Yes |

Download |

|||||||||

| Polymer | ✔ Yes |

Download |

|||||||||

| Elastomer | ✔ Yes |

Download |

|||||||||

| Polymer | ✔ Yes |

Download |

|||||||||

| Elastomer | ✔ Yes |

Download |

|||||||||

| Polymer | ✔ Yes | View | |||||||||

| Polymer | ✔ Yes | View |

Download |

||||||||

| Polymer | ✖ No | View | |||||||||

| Metal | ✔ Yes | View | |||||||||

| Polymer | ✔ Yes |

Download |

|||||||||

| Polymer | ✖ No | ||||||||||

| Polymer | ✖ No | View | |||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Elastomer | ✖ No |

Download |

|||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Elastomer | ✖ No |

Download |

|||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Polymer | ✔ Yes | View |

Download |

||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Elastomer | ✖ No | View |

Download |

||||||||

| Polymer | ✔ Yes | View |

Download |

||||||||

| Composite | ✖ No |

Download |

|||||||||

| Composite | ✖ No |

Download |

|||||||||

| Composite | ✖ No |

Download |

|||||||||

| Composite | ✖ No |

Download |

|||||||||

| Composite | ✖ No |

Download |

|||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Elastomer | ✖ No | View |

Download |

||||||||

| Elastomer | ✔ Yes | View |

Download |

||||||||

| Polymer | ✖ No |

Download |

|||||||||

| Polymer | ✔ Yes | View |

Download |

||||||||

| Polymer | ✔ Yes | View |

Download |

||||||||

| Elastomer | ✖ No | View |

Download |

||||||||

| Polymer | ✖ No | View |

Download |

||||||||

| Polymer | ✔ Yes | View |

Download |

| Title | Type of Material | Color | Biocompatibility | Flexural Modulus (ASTM D790) |

Tensile Strength (ASTM D638) |

Elongation at Break | Gallery | Technical Document | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mpa | ksi | Mpa | ksi | ||||||||

| Elastomer | ✔ Yes | 100 % |

Download |

||||||||

| Polymer | ✔ Yes | 643 | 94.1 | 24 | 3.42 | 33 % |

Download |

||||

| Elastomer | ✔ Yes | 75 % |

Download |

||||||||

| Polymer | ✔ Yes | 2300 | 322 | 84 | 12.2 | 12 % |

Download |

||||

| Elastomer | ✔ Yes | 1668.53 | 242 | 14 % |

Download |

||||||

| Polymer | ✔ Yes | 2250 | 327 | 5 % | View | ||||||

| Polymer | ✔ Yes | 1730 | 251 | 65 | 9.425 | 15 % | View |

Download |

|||

| Polymer | ✖ No | View | |||||||||

| Metal | ✔ Yes | View | |||||||||

| Polymer | ✔ Yes | 2700 | 392 | 130 | 19 | 28 % |

Download |

||||

| Polymer | ✖ No | 2510 | 364 | 110 | 16 | 3 % | |||||

| Polymer | ✖ No | 2220 | 320 | 50 | 6.91 | 8 % | View | ||||

| Polymer | ✖ No | 2200 | 319 | 86 | 12.4 | 13 % |

Download |

||||

| Polymer | ✖ No | 660 | 94.1 | 24 | 3.42 | 55 % |

Download |

||||

| Polymer | ✖ No | 3400 | 493 | 105 | 15.229 | 5 % |

Download |

||||

| Polymer | ✖ No | 1400 | 203 | 39 | 5.656 | 51 % |

Download |

||||

| Polymer | ✖ No | 1900 | 275 | 65 | 9.427 | 48 % |

Download |

||||

| Elastomer | ✖ No | 75 % |

Download |

||||||||

| Polymer | ✖ No | 9 % | View |

Download |

|||||||

| Polymer | ✖ No | 9000 | 1360 | 126 | 18.2 | 1 % |

Download |

||||

| Elastomer | ✖ No | 100 % |

Download |

||||||||

| Polymer | ✖ No | 2620 | 400 | 94.5 | 13.605 | 3 % |

Download |

||||

| Polymer | ✖ No | 900 | 130 | 100 % |

Download |

||||||

| Polymer | ✔ Yes | 1000 | 145 | 40 | 6 | 15 % | View |

Download |

|||

| Polymer | ✖ No | 1500 | 130 | 100 % | View |

Download |

|||||

| Elastomer | ✖ No | 100 % | View |

Download |

|||||||

| Polymer | ✔ Yes | 14 % | View |

Download |

|||||||

| Composite | ✖ No | 3600 | 522 | 81 | 12 | 25 % |

Download |

||||

| Composite | ✖ No | 22000 | 3191 | 200 | 29 | 1 % |

Download |

||||

| Composite | ✖ No | 21000 | 3046 | 420 | 61 | 1 % |

Download |

||||

| Composite | ✖ No | 26000 | 3771 | 240 | 35 | 1 % |

Download |

||||

| Composite | ✖ No | 51000 | 7397 | 540 | 78 |

Download |

|||||

| Polymer | ✖ No | 1200 | 175 | 40 | 5.8 | 4 % | View |

Download |

|||

| Polymer | ✖ No | 1500 | 220 | 80 | 10 | 5 % | View |

Download |

|||

| Polymer | ✖ No | 1200 | 174 | 50 | 7 | 7 % | View |

Download |

|||

| Polymer | ✖ No | 3800 | 550 | 130 | 19 | 3 % | View |

Download |

|||

| Polymer | ✖ No | 3000 | 430 | 130 | 19 | 5 % | View |

Download |

|||

| Elastomer | ✖ No | 100 % | View |

Download |

|||||||

| Elastomer | ✔ Yes | 100 % | View |

Download |

|||||||

| Polymer | ✖ No | 800 | 120 | 30 | 4 | 100 % |

Download |

||||

| Polymer | ✔ Yes | 1500 | 220 | 55 | 8 | 30 % | View |

Download |

|||

| Polymer | ✔ Yes | 1800 | 261 | 70 | 10.15 | 35 % | View |

Download |

|||

| Elastomer | ✖ No | 85 | 12 | 100 % | View |

Download |

|||||

| Polymer | ✖ No | 2400 | 348 | 57.5 | 8.34 | 10 % | View |

Download |

|||

| Polymer | ✔ Yes | 1730 | 251 | 65 | 9.425 | 15 % | View |

Download |

|||

| Title | Type of Material | Color | Flexural Modulus | Flexural Strength | Tensile Modulus | Yield Strength | UTS | Elongation at Break | Impact Resistance - Notched Izod | Impact Resistance - Notched Izod | Heat Deflection - Temperature | Heat Deflection - Temperature | Hardness | Density | Gallery | Technical Document | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (ASTM D790) | (ASTM D790) | (ASTM D638) | (ASTM D638 (Polymer), ASTM E9 (Metal)) | (ASTM D638) | (ASTM D256 Method A) | (ASTM D256 Method B) | (0.455 MPa (66 psi), ASTM D648) | (1.82 MPa (264 psi), ASTM D648) | ASTM E18 | ASTM D2240 | (g/cm3) | Relative (%) | |||||||||||||||||

| Mpa | ksi | Mpa | ksi | Mpa | ksi | Mpa | ksi | Mpa | ksi | J/m | ft-lb/in | KJ/m2 | ft-lb/in2 | °C | °F | °C | °F | Rockwell HRC | Shore D | Shore A | |||||||||

| Elastomer | 2.32 | .468 | 100 % | 50 |

Download |

||||||||||||||||||||||||

| Polymer | 643 | 94.1 | 24 | 3.42 | 994 | 149 | 29.1 | 33 % | 114 | 2.13 | 98 | 1.84 | 46 | 115 | 40 | 104 | 75 |

Download |

|||||||||||

| Elastomer | 8.9 | 1.29 | 75 % | 80 |

Download |

||||||||||||||||||||||||

| Polymer | 2300 | 322 | 84 | 12.2 | 52 | 7.5 | 12 % | 35 | 0.658 | 67 | 152 | 54 | 129 | 78 |

Download |

||||||||||||||

| Elastomer | 1668.53 | 242 | 35.71 | 5.18 | 14 % | 24.77 | 0.464 | 67.9 | 154 | 49.4 | 121 | 77 |

Download |

||||||||||||||||

| Polymer | 2250 | 327 | 2500 | 362 | 63.7 | 9.25 | 28.1 | 4.08 | 5 % | 30.2 | 4.8 | View | |||||||||||||||||

| Polymer | 1730 | 251 | 65 | 9.425 | 1700 | 247 | 48 | 6.96 | 15 % | 3.5 | .33 | 175 | 347 | 95 | 203 | 80 | 1.01 | View |

Download |

||||||||||

| Polymer | 1545 | 224 | 12930 | 1875 | View | ||||||||||||||||||||||||

| Metal | 430 | 62.4 | 530 | 76 | View | ||||||||||||||||||||||||

| Polymer | 2700 | 392 | 130 | 19 | 3720 | 540 | 28 % | 140 | 284 | 1.3 |

Download |

||||||||||||||||||

| Polymer | 2510 | 364 | 110 | 16 | 2500 | 363 | 3 % | 1.27 | |||||||||||||||||||||

| Polymer | 2220 | 320 | 50 | 6.91 | 2400 | 350 | 30 | 4.47 | 8 % | 100 | 1.9 | 104 | 220 | 100 | 212 | View | |||||||||||||

| Polymer | 2200 | 319 | 86 | 12.4 | 2600 | 377 | 61 | 8.876 | 13 % | 18.7 | 0.351 | 77.5 | 171.5 | 62.4 | 144.3 |

Download |

|||||||||||||

| Polymer | 660 | 94.1 | 24 | 3.42 | 1000 | 149 | 28 | 1.9 | 55 % | 114 | 2.13 | 41 | 105 |

Download |

|||||||||||||||

| Polymer | 3400 | 493 | 105 | 15.229 | 4100 | 595 | 69 | 10.007 | 5 % | 23 | 0.43 | 77 | 170 | 60 | 140 |

Download |

|||||||||||||

| Polymer | 1400 | 203 | 39 | 5.656 | 1500 | 218 | 33 | 4.786 | 51 % | 67 | 1.2 | 52 | 126 | 45 | 113 |

Download |

|||||||||||||

| Polymer | 1900 | 275 | 65 | 9.427 | 2200 | 329 | 56 | 6.671 | 48 % | 40 | 0.75 | 63 | 145 | 53 | 127 |

Download |

|||||||||||||

| Elastomer | 8.9 | 1.29 | 75 % | 80 |

Download |

||||||||||||||||||||||||

| Polymer | 1600 | 232 | 29 | 4.2 | 9 % | 9.5 | 100 | 212 | 60 | 140 | .87 | View |

Download |

||||||||||||||||

| Polymer | 9000 | 1360 | 126 | 18.2 | 10000 | 1460 | 65 | 9.460 | 1 % | 16 | 0.3 | 163 | 325 | 82 | 180 |

Download |

|||||||||||||

| Elastomer | 2.32 | .468 | 100 % | 50 |

Download |

||||||||||||||||||||||||

| Polymer | 2620 | 400 | 94.5 | 13.605 | 2.9 | 421 | 58.3 | 8.456 | 3 % | 24.2 | 0.45 | 238 | 460.4 | 101 | 213.8 |

Download |

|||||||||||||

| Polymer | 900 | 130 | 1000 | 145 | 25 | 4 | 35 | 5 | 100 % | 75 | 1.4 | 55 | 130 | 55 | 130 | 77 | 10.7 |

Download |

|||||||||||

| Polymer | 1000 | 145 | 40 | 6 | 1300 | 190 | 15 | 2 | 35 | 35 | 15 % | 30 | 0.6 | 50 | 120 | 40 | 100 | 81 | 1.12 | View |

Download |

||||||||

| Polymer | 1500 | 130 | 3900 | 39 | 6 | 52 | 8 | 100 % | 71.6 | 200 | 390 | 53 | 127.4 | 79 | 1.134 | View |

Download |

||||||||||||

| Elastomer | 6 | 0.87 | 15 | 2.2 | 100 % | 73 | 1.03 | View |

Download |

||||||||||||||||||||

| Polymer | 2600 | 377 | 46 | 6.67 | 14 % | 3 | 3 | 170 | 338 | 110 | 230 | 1.03 | View |

Download |

|||||||||||||||

| Composite | 3600 | 522 | 81 | 12 | 1400 | 203 | 25 % | 330 | 6.18 | 145 | 293 | 1.1 |

Download |

||||||||||||||||

| Composite | 22000 | 3191 | 200 | 29 | 21000 | 3046 | 1 % | 105 | 221 | 1.5 |

Download |

||||||||||||||||||

| Composite | 21000 | 3046 | 420 | 61 | 21000 | 3046 | 1 % | 3100 | 58.08 | 150 | 302 | 1.5 |

Download |

||||||||||||||||

| Composite | 26000 | 3771 | 240 | 35 | 27000 | 3916 | 1 % | 2000 | 37.47 | 105 | 221 |

Download |

|||||||||||||||||

| Composite | 51000 | 7397 | 540 | 78 | 60000 | 8702 | 960 | 17.98 | 105 | 221 | 1.4 |

Download |

|||||||||||||||||

| Polymer | 1200 | 175 | 40 | 5.8 | 29 | 4.2 | 45 | 6 | 4 % | 20 | 0.36 | 61 | 142 | 45 | 113 | 1.1 | View |

Download |

|||||||||||

| Polymer | 1500 | 220 | 80 | 10 | 1400 | 200 | 30 | 4.4 | 5 % | 20 | 0.4 | 50 | 122 | 40 | 104 | 1.1 | View |

Download |

|||||||||||

| Polymer | 1200 | 174 | 50 | 7 | 1400 | 200 | 30 | 4.4 | 30 | 4.4 | 7 % | 30 | 0.6 | 45 | 113 | 35 | 95 | 86 | 1.2 | View |

Download |

||||||||

| Polymer | 3800 | 550 | 130 | 19 | 3900 | 570 | 85 | 12 | 3 % | 15 | 0.3 | 230 | 450 | 200 | 390 | 92 | 1.2 | View |

Download |

||||||||||

| Polymer | 3000 | 430 | 130 | 19 | 2800 | 410 | 80 | 10 | 80 | 10 | 5 % | 45 | 0.8 | 130 | 270 | 120 | 250 | 89 | 1.16 | View |

Download |

||||||||

| Elastomer | 8 | 1.2 | 9 | 1.3 | 100 % | 68 | 1.03 | View |

Download |

||||||||||||||||||||

| Elastomer | 3 | 0.44 | 3.5 | 0.5 | 100 % | 35 | 1.07 | View |

Download |

||||||||||||||||||||

| Polymer | 800 | 120 | 30 | 4 | 700 | 100 | 15 | 2 | 25 | 4 | 100 % | 40 | 0.7 | 70 | 155 | 45 | 110 | 71 | 1.05 |

Download |

|||||||||

| Polymer | 1500 | 220 | 55 | 8 | 1700 | 245 | 40 | 6 | 40 | 6 | 30 % | 15 | 0.3 | 60 | 140 | 45 | 110 | 80 | 1.08 | View |

Download |

||||||||

| Polymer | 1800 | 261 | 70 | 10.15 | 1800 | 261 | 35 % | 4.5 | 2.14 | 185 | 365 | 54 | 129 | 80 | 1.05 | View |

Download |

||||||||||||

| Elastomer | 85 | 12 | 17 | 2 | 100 % | 90 | View |

Download |

|||||||||||||||||||||

| Polymer | 2400 | 348 | 57.5 | 8.34 | 2500 | 363 | 10 % | 3 | 1.43 | 174 | 345 | 114 | 237 | 82 | 1.3 | View |

Download |

||||||||||||

| Polymer | 1730 | 251 | 65 | 9.425 | 1700 | 247 | 48 | 6.96 | 15 % | 3.5 | 3.33 | 175 | 347 | 95 | 203 | 80 | 1.01 | View |

Download |

||||||||||

Get a quote or request help

We make it easy to get a quote or request help with your material selection.