February 14, 2020: This week we’ve been busy unboxing, installing, powering up and testing the world’s first Powerfuse S! It’s a revolutionary post-processing system for 3D printed parts that rivals the surface quality of injection molding. VaporFuse Surfacing is a game-changer for the medical device, food service, automotive and industrial markets.

With first-in-world tech, Spicer engineers on cusp of revolutionizing 3D printing industry – as published in the Lakes Area Review

February 1, 2020: By Brett Blocker, Editor, Lakes Area Review – Two-thousand miles removed from the tech hubs of Silicon Valley and an ocean away from the burgeoning markets of Beijing, the small town of Spicer is about the last place one would expect to find the frontline of fabrication. But tucked behind rows of oak trees at the end of a winding wooded driveway, in an otherwise unassuming building along 113th Ave NE, a trio of engineering brothers are, quite literally, developing the “cutting edge” of 3D printing as the manufacturing industry knows it.

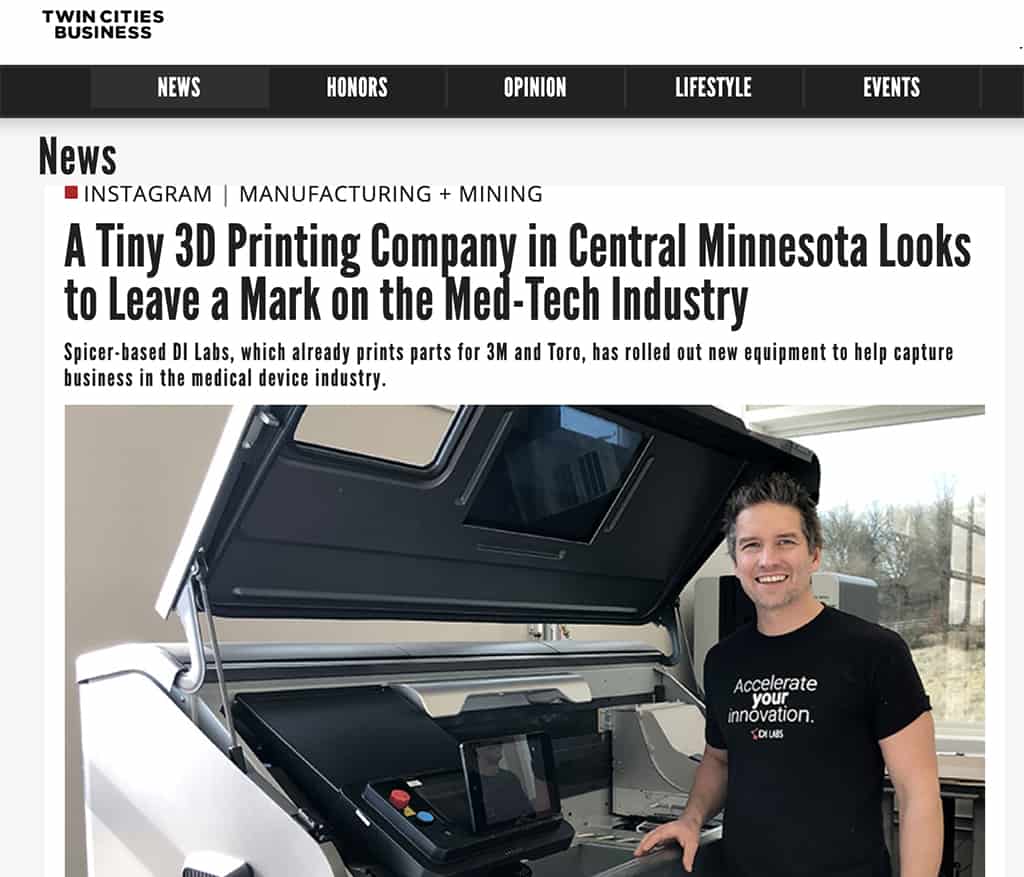

DI Labs Featured in Twin Cities Business Magazine

January 14, 2020: As a start to 2020, we were interviewed by Dan Niepow, an Editor from Twin Cities Business. We are proud to be a small company making a big impact in our industry!

DI Labs is a Global First with Powerfuse S Finishing Technology

December 11, 2019: Last December, we were proud to host the DyeMansion development team all the way from their headquarters in Munich, Germany. Their visit completed our purchase of the first Powerfuse S machine in the world. It’s a vaporfuse surfacing technology that will vastly expand our ability to serve our growing and diverse customer base.

DI Labs Adds Engineering-Grade, Full-Color 3D Printing

November 18, 2019: DI Labs recently expanded their technology portfolio with a new machine that is breaking ground in the industry due to its ability to print brilliant, full-color prototypes with the mechanical properties and structural integrity of injection molded parts. Once again, DI Labs will be one of the first companies in the region with the technology.

DI Labs Acquires 3D Printing Startup, Advocate3D

OCTOBER 2019: The team at DI Labs is proud to announce the acquisition of 3D printing startup, Advocate 3D, a full-service prototyping service bureau located southwest of the Minneapolis metro. The move allows DI Labs to grow its technology portfolio and expand its client base throughout the Midwest.

Brian Douglass Named Runner Up at 30th Annual AMUG Technical Competition

APRIL 2018: Brian Douglass of DI Labs was recently named runner up in the Additive Manufacturing Users Group (AMUG) Technical Competition Advanced Concepts Category with a creative gasket installation tool. The competition provides a forum for users of additive manufacturing technologies to display their unique applications as well as their finishing capabilities.

DI Labs Announces Addition of New Technology, Expanded Material and Growing Team

DECEMBER 2018: DI Labs announced the addition of Minnesota’s first HP Multi Jet Fusion (MJF) to their additive manufacturing capabilities. Since then, they have invested in several additional 3D printers; most recently adding an HP Jet Fusion 3D 4210 Printing system.

SciTechsperience Internship Provides a Great Foundation While Serving Client Needs

NOVEMBER 2018: SciTechsperience interns Joseph Fernandez and Matthew Pearce joined the Douglass brothers this last summer to assist with engineering projects and learn more about product testing and design. “It’s actually somewhat serendipitous from my perspective,” Carl Douglass said, “As we’ve had projects for both Mathew and Joseph, those projects have been great foundation builders for where they both want to be in their careers. It’s also served the needs that we’ve had to support our customers. It’s just been perfect.”

DI Labs Adds High Resolution, Industrial 3D Scanning Technology

APRIL 2018: DI Labs is once again expanding their technology portfolio with the addition of high resolution 3D scanning. They have purchased two Artec industrial scanners which are some of the most advanced in the industry. This new technology allows them to capture and record the exact size, surface quality and structure of physical objects then convert them to digital 3-dimensional computer models.

- Page 2 of 2

- 1

- 2