Renowned sculptor, Richard Fishman, collaborates with DI Labs to connect art, science and technology

Richard Fishman is a world-renowned sculptor and designer who explores the connection between the arts, science, and technology. He recently spent several days at DI Labs collaborating on the production of a new sculpture based on organic shapes found in nature. Fishman is an Emeritus Professor of Visual Art at Brown University and the founding Director of the Granoff Center …

Fully Functional Manifold Prototype Performs Under Real World Testing

“By combining engineering expertise with additive technology we created a full-size, fully functional prototype for real world testing.” Project Brief DI Labs was approached by an aftermarket automotive tuning company doing work for European sports cars. They were interested in developing a fully functional prototype of an intake manifold that would accept their supercharger and create forced induction. It …

Full Scale Prototype Larger Than The Printer Itself

This full-scale prototype was an extremely complex additive manufacturing project. Our aerospace customer was accelerating the development of a new aircraft for a growing global market. They required a full-size fuselage model with a high degree of dimensional accuracy so they could perform internal testing for ergonomics, cockpit design, and operation. “We produced for them a 10′ x 4.5′ fuselage …

Customized PPE with Volume Production

Many industries rely on PPE (Personal Protective Equipment) to keep their workers safe, but the COVID-19 crisis has escalated that need to entirely new levels. DI Labs has a large client in the food processing industry that must now provide face shields to all of its front line workers in order to maintain safe operations. With much at stake, they …

Innovating to Elevate PPE Safety for Healthcare Professionals

As the nation’s critical need for PPE escalates, DI Labs is intensely focused on innovating and testing design concepts for key items such as N95 masks. We are motivated by a desire to help but also by a concern for the safety offered by 3D printed solutions that are currently being circulated for use by our healthcare workers. “Producing PPE …

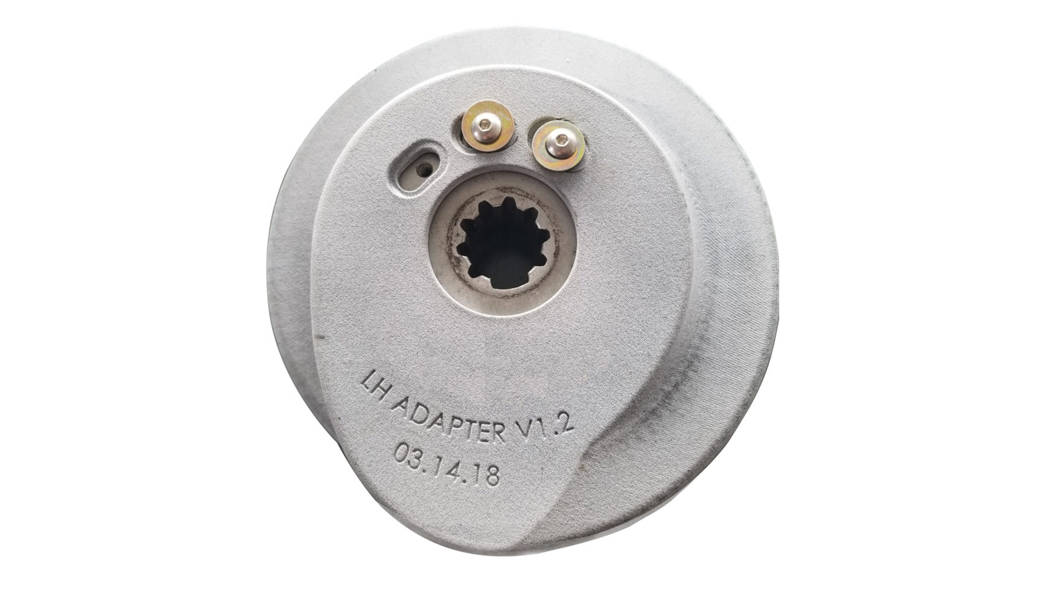

3D Printed Sleeves Keep Product Launch on Track

“Designing and producing 3D printed sleeves for our client’s perforator wheels was 1/7th the capital investment and many weeks faster than custom machining new wheels.” Project Brief Our client manufactures plastic tubing and was scaling the launch of a new product which was being produced on existing equipment. As they were testing their downstream manufacturing setup, they discovered that …

- Page 1 of 2

- 1

- 2