Fully Functional Manifold Prototype Performs Under Real World Testing

“By combining engineering expertise with additive technology we created a full-size, fully functional prototype for real world testing.” Project Brief DI Labs was approached by an aftermarket automotive tuning company doing work for European sports cars. They were interested in developing a fully functional prototype of an intake manifold that would accept their supercharger and create forced induction. It …

Full Scale Prototype Larger Than The Printer Itself

This full-scale prototype was an extremely complex additive manufacturing project. Our aerospace customer was accelerating the development of a new aircraft for a growing global market. They required a full-size fuselage model with a high degree of dimensional accuracy so they could perform internal testing for ergonomics, cockpit design, and operation. “We produced for them a 10′ x 4.5′ fuselage …

Customized PPE with Volume Production

Many industries rely on PPE (Personal Protective Equipment) to keep their workers safe, but the COVID-19 crisis has escalated that need to entirely new levels. DI Labs has a large client in the food processing industry that must now provide face shields to all of its front line workers in order to maintain safe operations. With much at stake, they …

Innovating to Elevate PPE Safety for Healthcare Professionals

As the nation’s critical need for PPE escalates, DI Labs is intensely focused on innovating and testing design concepts for key items such as N95 masks. We are motivated by a desire to help but also by a concern for the safety offered by 3D printed solutions that are currently being circulated for use by our healthcare workers. “Producing PPE …

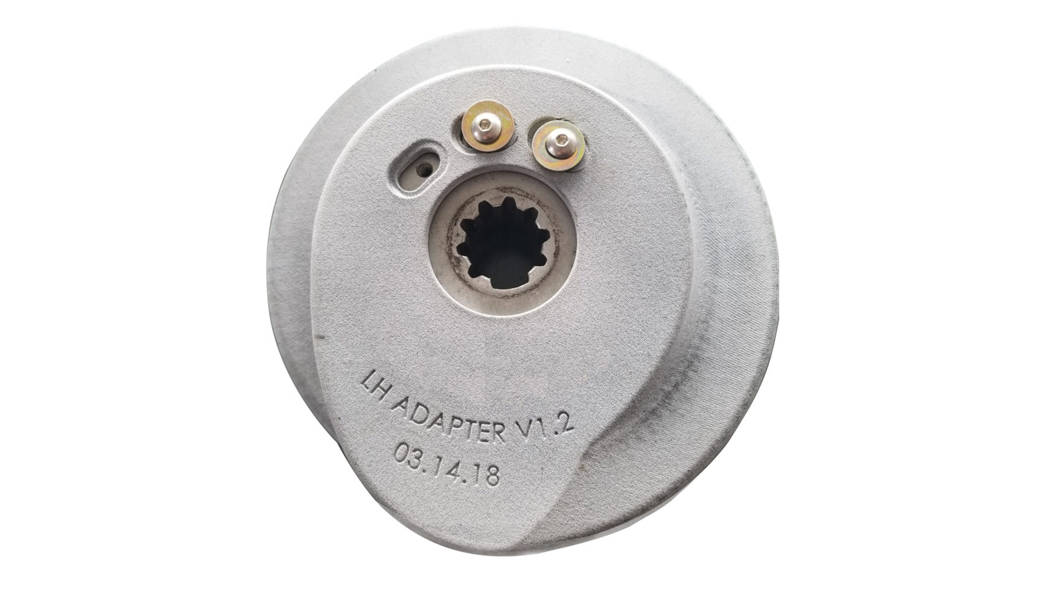

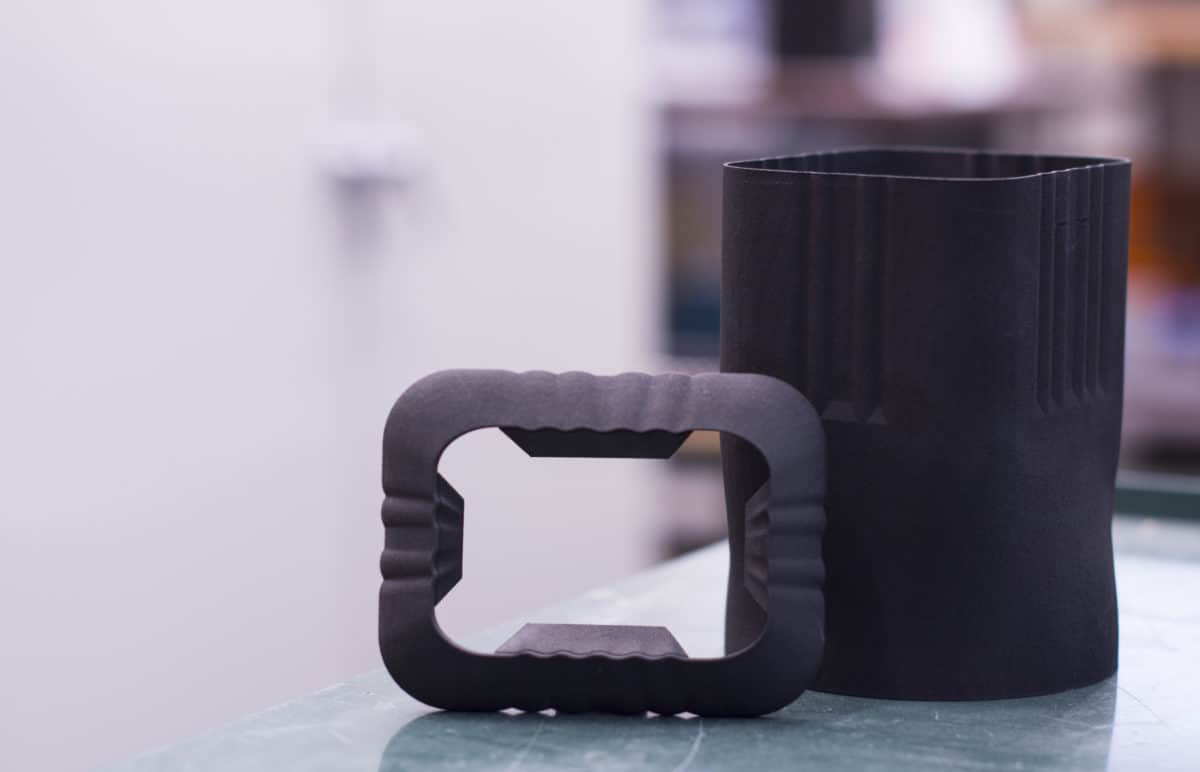

3D Printed Sleeves Keep Product Launch on Track

“Designing and producing 3D printed sleeves for our client’s perforator wheels was 1/7th the capital investment and many weeks faster than custom machining new wheels.” Project Brief Our client manufactures plastic tubing and was scaling the launch of a new product which was being produced on existing equipment. As they were testing their downstream manufacturing setup, they discovered that …

Aeroponic Basket Design Advances Organic Strategy & Increases Productivity

“Through rapid iteration and testing we far surpassed our original design goals for organic by also increasing yields and growth speeds.” Project Brief Lettuce Abound is a Minnesota company and pioneer in organic farming. Recently, they began using aeroponics as part of a forward-looking expansion strategy. They came to DI Labs for a custom-designed aeroponic basket that would hold …

Custom Designed Tradeshow Display Engages Audience

Our client needed to feature a very unique product for residential construction applications at a national tradeshow. We designed a solution that not only showcased the assembled product in a simulated construction setting but included a central monitor with a looping testimonial video. The display attracted a record number of prospects resulting in an extremely successful show. solution: DI Labs provided an end-to-end …

Product Redesign Vastly Reduces Components, Labor and Costs

Our client purchased a business featuring an overly complex and labor-intensive product line. He brought it to DI Labs looking for ways to streamline manufacturing and assembly, which would ultimately reduce costs and improve margins. Our solution was to redesign the main component of the product which ultimately allowed us to replace 15 parts with one, newly-designed, injection-molded part. solution: …

New Fitting Design to Enhance Core Product

Our client manufactures a metal product that requires a plastic fitting. The current fitting was aesthetically unappealing and detracted from the streamlined look of our client’s product. We solved that problem by custom designing a new fitting that couples from the inside and can be colorized to match the metal. solution: DI Labs provided a full-service solution from custom design …

- Page 1 of 2

- 1

- 2