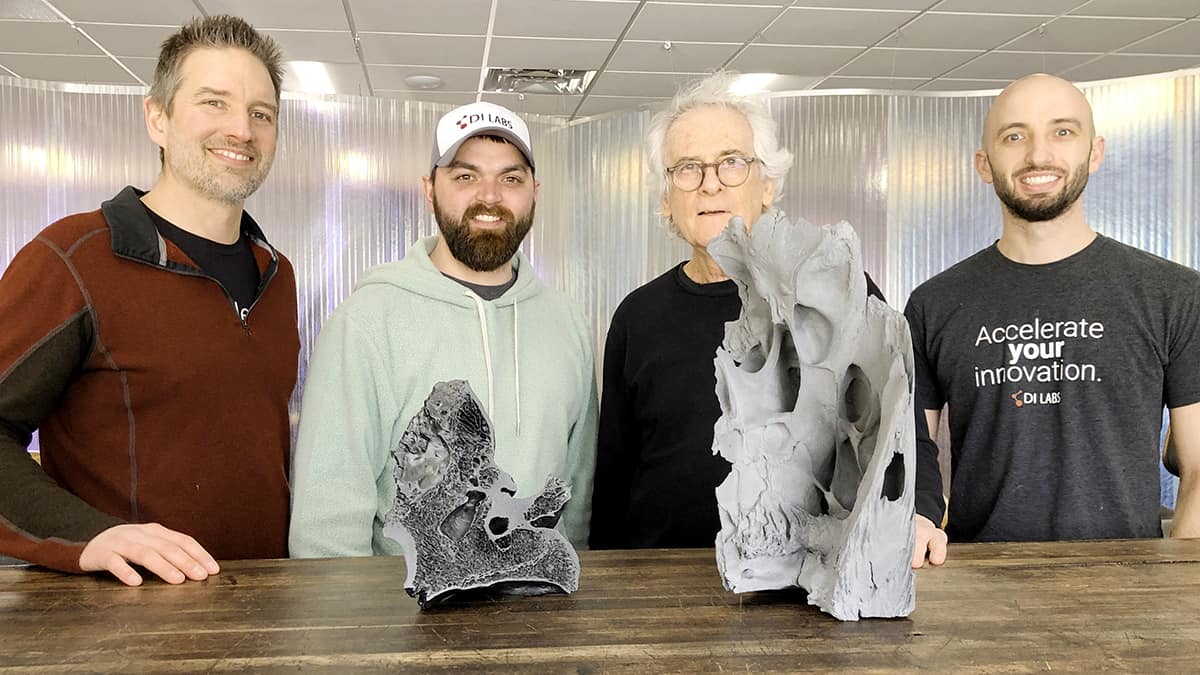

Renowned sculptor, Richard Fishman, collaborates with DI Labs to connect art, science and technology

DI Labs was proud to collaborate with such a creative, accomplished and visionary artist to explore another groundbreaking application for additive manufacturing. Richard inspired our team to push boundaries and achieve next level results for this stunning fine arts project.

Project Brief

Richard Fishman is a world-renowned sculptor and designer who explores the connection between the arts, science, and technology. He recently spent several days at DI Labs collaborating on the production of a new sculpture based on organic shapes found in nature. Fishman is an Emeritus Professor of Visual Art at Brown University and the founding Director of the Granoff Center for the Creative Arts at Brown.

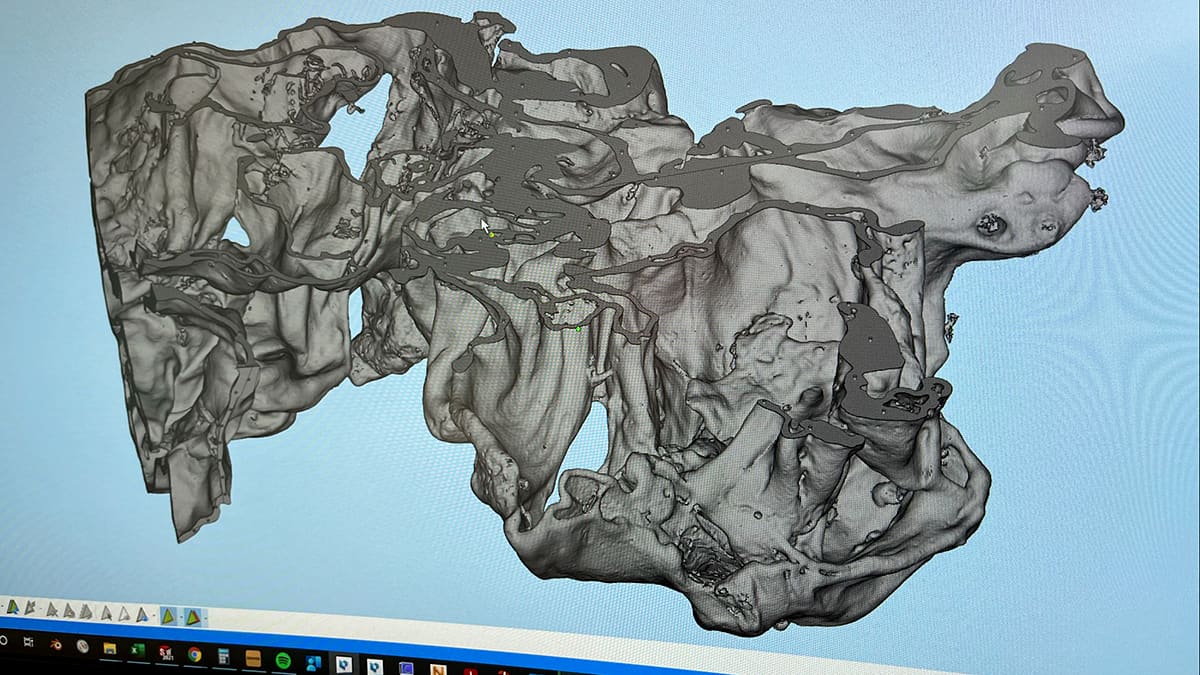

For this piece, Fishman’s creative process began with an organic shape then turned technical when it was scanned using Computerized Tomography (CT) technology. His large, highly complex CT scans were then sent to DI Labs to be meticulously converted to 3D models. Fishman worked closely with DI Labs to review surface qualities and resolution before files were scaled to larger-than-life dimensions and designed to meet the build specifications for our HP Multi-Jet Fusion™ printing system.

“HP Multi-Jet Fusion™ was an excellent technology choice for this organic structure due to its high precision and excellent printed aesthetics. We used Nylon PA12 as a material due to its external surface qualities which work well with Richard’s custom colorization process,” explains Alex Benson, DI Labs Solutionologist.

Richard Fishman’s final sculpture was printed in 50 pieces then assembled to a final size of 36” x 36” x 27.” This commissioned art piece will be finished by Richard to capture his unique perspective then presented to his client in London, UK. DI Labs was proud to collaborate with such a creative, accomplished, and visionary artist to explore another groundbreaking application for additive manufacturing. Richard inspired our team to push boundaries and achieve next-level results for this stunning fine arts project.

To learn more about Richard Fishman’s work:

Instagram: https://www.instagram.com/richard_fishman/?hl=en

Website: http://www.richard-fishman.com/

To learn more about MJF technology or other unique additive manufacturing applications:

[email protected]

Project Details

- Manage and convert highly complex and data-intensive CT scans

- Larger-than-life final piece

- Complex construction & intricate surface quality details

- Design for HP Multi-Jet Fusion technology

- Design for printing in 50 pieces

- Precision, permanent assembly of 50 pieces to create a 36” x 36” x 27” sculpture

- Design for additive

- Prototyping

- Precision assembly process