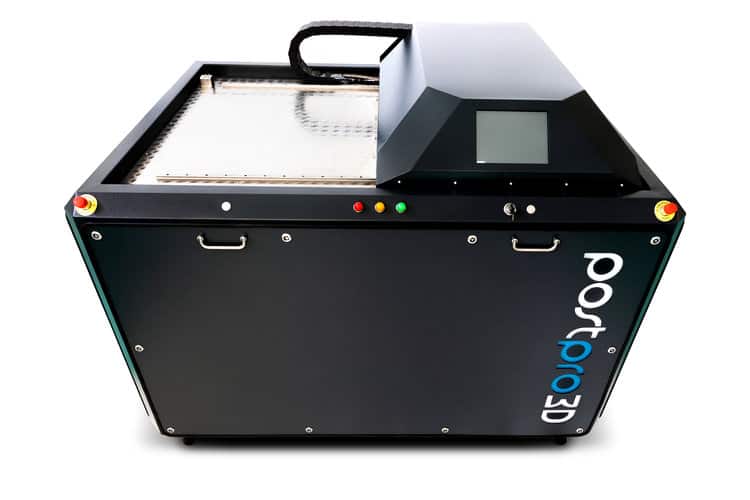

July 13, 2020: Fueled by the needs of the market, DI Labs has made a bold move with the addition of an AMT PostPro3D® machine. It’s an automated post-processing system that can create smooth, sealed, sanitizable surfaces on parts printed with a wide variety of polymer-based technologies including HP Multi Jet Fusion and Fused Filament Fabrication. The results rival the quality and consistency of injection molding.

In late 2019, DI Labs began discussions with AMT to assess the PostPro3D technology as a tool to meet the rising demand for premium quality surface finishes in the medical, food, aerospace, automotive and consumer goods industries. The addition was a strategic move by DI Labs and demonstrates their commitment to keeping pace with emerging market needs. The new PostPro3D machine is part of an expansion project which will make DI Labs the premiere and most technology-rich digital manufacturing and innovation center in the Midwest.

“We thoroughly evaluated the PostPro3D process to experience first-hand the high level of finishing quality it creates, especially for parts produced on HP Multi Jet Fusion printers. This machine will allow us to provide full-service, end-to-end production of parts that require a fully sealed surface finish without sacrificing dimensional tolerances or part features. We currently offer several advanced finishing processes for smoothing, coloring, painting, and plating, and are proud to add the PostPro3D technology to our workflow. It’s all part of our ongoing mission to help our customers accelerate their innovation,” explained Carl Douglass, Co-Founder and President of DI Labs.

DI Labs is located in Minnesota and owned by brothers Carl, Brian and Sean Douglass. They have created a unique company culture founded on the motto “there’s always a solution,” which has allowed them to defy the odds and build one of the fastest-growing technology companies in the Midwest.