Industrial Grade Printing

Engineered Solutions

ITAR Registered

High Volume Orders

99.9% On-time Delivery

White Glove Service

ISO 9001:2015 Certified

ISO 9001:2015 Certified

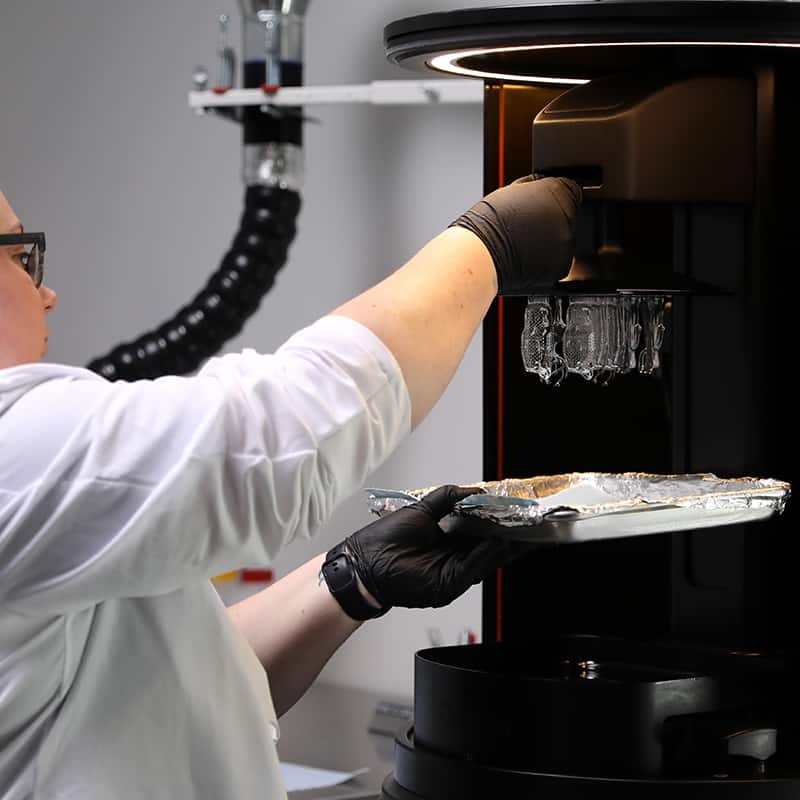

DI Labs was founded on technical, operational, and quality excellence. As our company has expanded over the years, we've developed and improved our quality management, ERP, and MES systems to maintain our uncompromising quality at scale.

Independent certification to ISO 9001:2015 has been on our roadmap, but we've been intentional to get the certification at the right time, once we achieved critical mass. In late 2023, we decided to become audited and ultimately certified. The audit process was seamless and we're proud to announce our official certification under ISO 9001:2015. We recognize the importance of independent certification but we won't stop there. We're driven to continuous improvement and holding ourselves and our technologies to the highest standards.

Welcome to our

Solutionology Podcast

Check out our Solutionology Podcast! Hosts, DI Labs Co-Founders Brian and Carl Douglass, are “solutionologists” who solve problems and create new opportunities for customers by leveraging their diverse and powerful fleet of cutting-edge additive technologies. They'll be using this platform to have discussions on a wide variety of topics, often bringing on special guests and other industry experts.

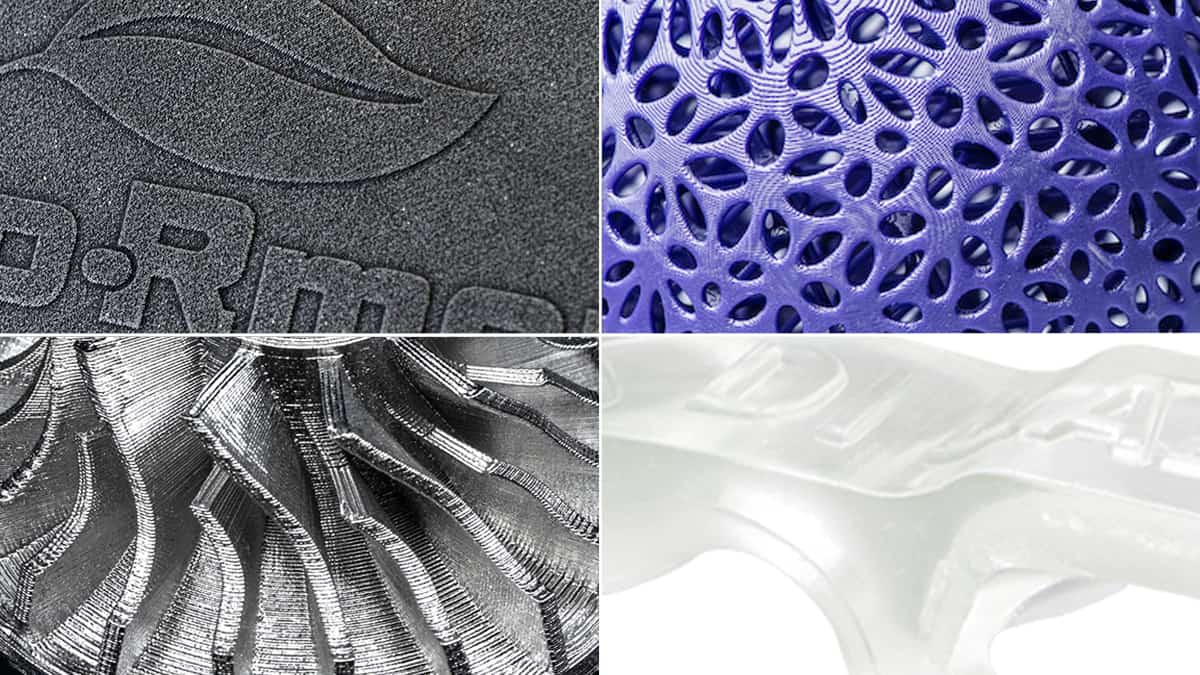

9 Premium Technologies

Reference & Compare

See our premium additive manufacturing technologies to better understand which one may be right for your project.

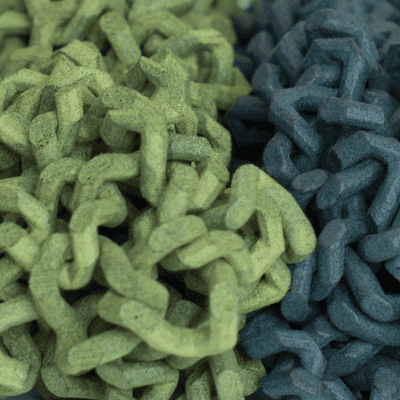

80+ Materials

Reference & Compare

See our available materials, do simple comparisons and get the details of their mechanical properties.

A Project Profile

An EV Charger Housing from Concept to Production in 8 Days

PHYTEC contacted DI Labs with an urgent need: they had developed a state-of-the-art cloud-connected EV charging solution, but needed a housing for demonstration purposes.

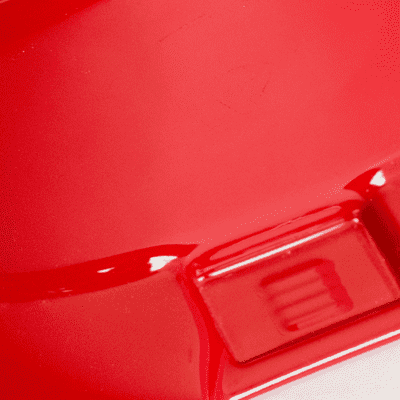

Offering Premium Finishing Options

Standard

Smoothing

Dyeing

Painting

Finishing is one of the most critical aspects of additive manufacturing, preparing parts to meet the expectations, demands and standards of a wide variety of premium applications such as aerospace, food service, medical device and consumer goods. We offer some of the world’s most advanced finishing options.

The Value of Additive Through a Traditional Product Lifecycle

Become a Solutionologist

DI Labs is rapidly growing our technologies, our lab and most importantly, our team. We are bootstrapping entrepreneurs and self-proclaimed solutionologists with a passion for building a unique culture where creative, driven people can advance their careers and be part of our entrepreneurial journey.