Industrial Grade Printing

Engineered Solutions

ITAR Registered

High Volume Orders

99.9% On-time Delivery

White Glove Service

ISO 9001:2015 Certified

Welcome to our

Solutionology Stories Podcast & Newsletter

Check out our Solutionology Stories Podcast! Hosts, DI Labs Co-Founders Brian and Carl Douglass, are product development engineers and “solutionologists” who help customers leverage digital manufacturing by taking a solutions-first approach. Watch each episode on this website, on YouTube or in our monthly Linkedin newsletter.

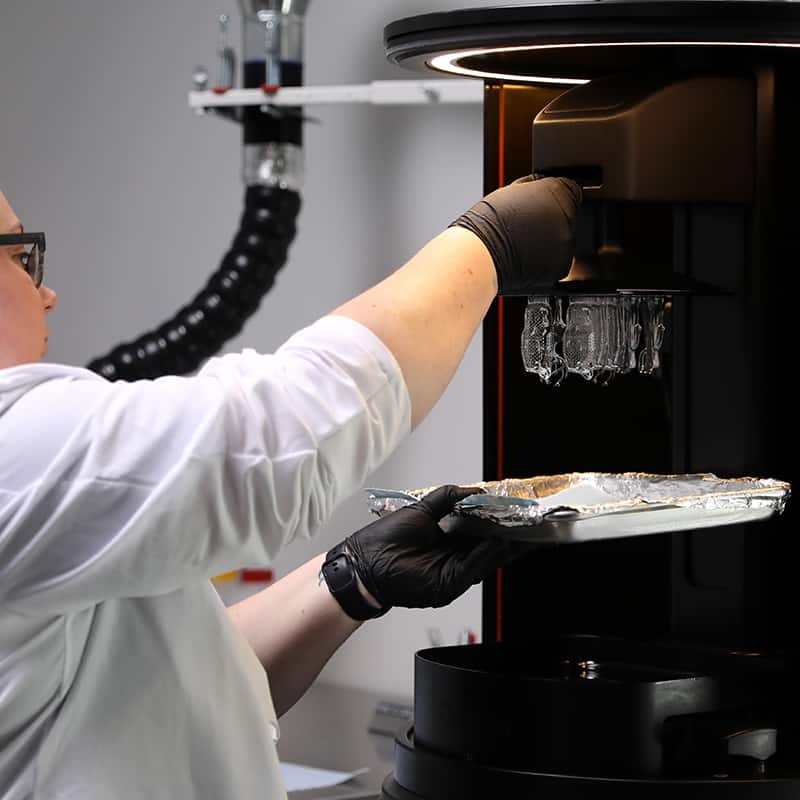

An Injection Mold Alternative for Medical Device Components & Assemblies

DI Labs offers an alternative to injection molding for medical device developers who want to accelerate their journey. Our advanced additive manufacturing technologies and highly controlled digital workflows empower teams to move quickly and efficiently through each development phase with unlimited design iteration and injection-mold-quality parts from concept to commercialization.

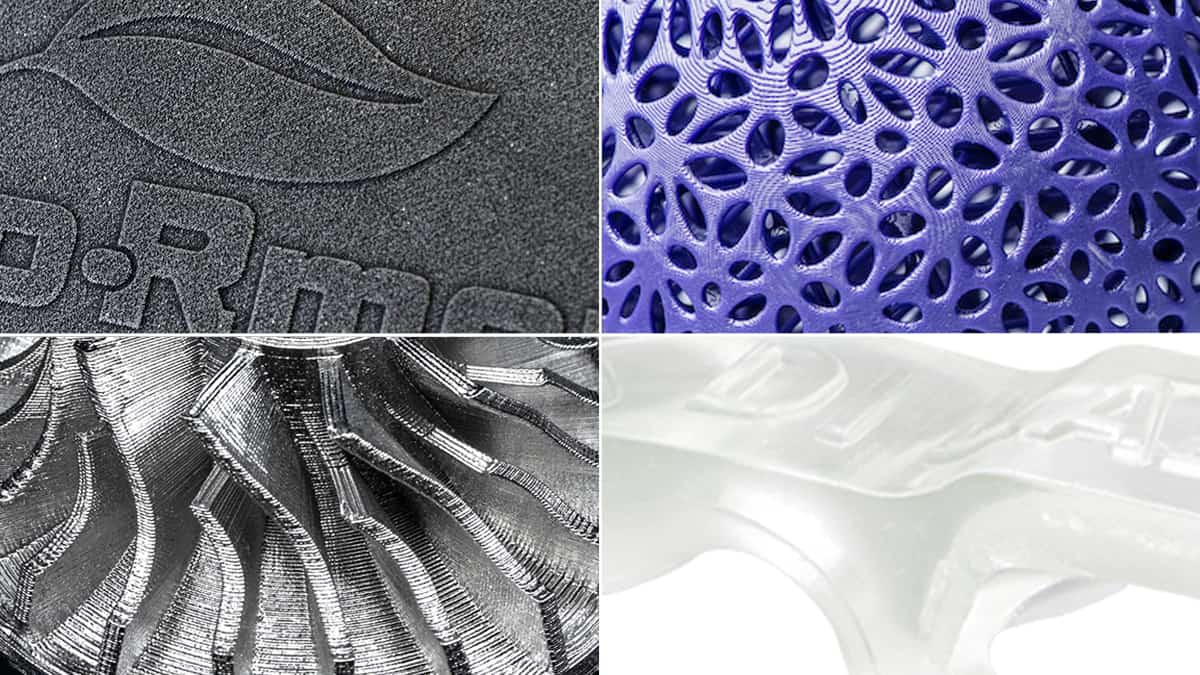

9 Premium Technologies

Reference & Compare

See our premium additive manufacturing technologies to better understand which one may be right for your project.

100+ Materials

Reference & Compare

See our available materials, do simple comparisons and get the details of their mechanical properties.

A Project Profile

A Commitment to Innovation: Getting a 4' Septic Chamber From Concept to Launch

Join DI Labs COO and Product Designer Brian Douglass, along with our client's leadership and technical team on location at a live testing site to recap the 8-year product development journey behind a revolutionary new septic chamber. This groundbreaking project was designed by DI Labs and resulted in a four-model product portfolio for Prinsco, a leader in water management solutions. Hear about the commitment, dedication, challenges, and collaboration that drove this innovation from concept to market launch.

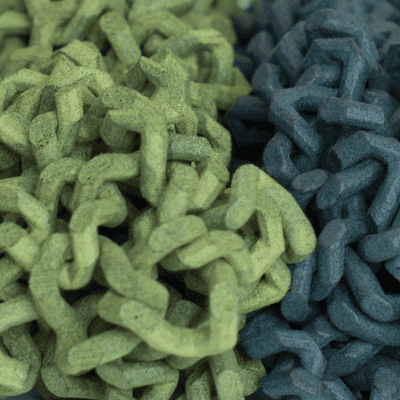

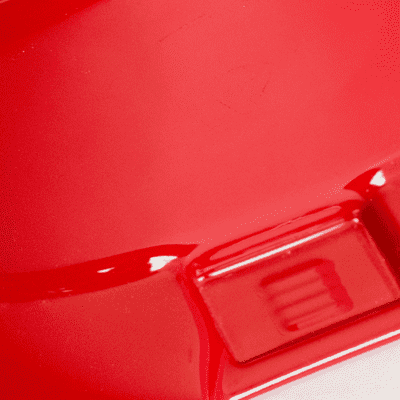

Offering Premium Finishing Options

Standard

Smoothing

Dyeing

Painting

Finishing is one of the most critical aspects of additive manufacturing, preparing parts to meet the expectations, demands and standards of a wide variety of premium applications such as aerospace, food service, medical device and consumer goods. We offer some of the world’s most advanced finishing options.

Become a Solutionologist

DI Labs is rapidly growing our technologies, our lab and most importantly, our team. We are bootstrapping entrepreneurs and self-proclaimed solutionologists with a passion for building a unique culture where creative, driven people can advance their careers and be part of our entrepreneurial journey.